- (+86)-595-2866-7678

- service@vancharli.com

- Within 24 hours response from our salesman

A custom disc golf bag is more than a backpack — it’s an essential part of the game. Vancharli offers OEM & ODM manufacturing for global brands, combining functionality, durability, and strong brand presence.

Choose a base model and tailor it to your audience—tournament pros, club players, or weekend beginners.

Each base can be re-engineered for capacity, pocketing, padding, and branding—so your line stands out in both play and retail.

Features that matter on the course—capacity, structure, weather-readiness, and brand presence.

Manufacturing strength × sports-specific design—your reliable partner for scaling a disc golf line.

Sport-Tuned Engineering — Layouts tested with players to balance access, capacity, and weight.

One-Stop OEM/ODM — From ideation and tech packs to tooling and mass production.

Multi-Country Supply Chain — China/Vietnam/Myanmar/Indonesia for capacity and risk dispersion.

Low MOQ & Fast Lead Time — Start at 300 pcs; 45–60 days after sample approval.

Retail-Ready Branding — Packaging, hangtags, and colorways tailored to your channels.

Your custom disc golf bag should reflect both your brand and your players’ real needs. That’s why we offer extensive customization options that go beyond surface printing — from technical materials and functional upgrades to shape engineering and premium branding solutions.

We offer a wide selection of performance materials to ensure the bag is ready for any course condition:

High-denier nylon and polyester for strength and abrasion resistance.

TPU/PU coating for water resistance and easy mud cleaning.

Ripstop reinforcement in high-wear zones to extend lifespan.

Breathable mesh or padded back panels to increase comfort.

Optional fleece lining or smooth interior fabric for easier disc access.

These combinations allow you to match durability and comfort with your target market’s price point.

Branding goes far beyond a single print. We help you create a professional retail look that boosts shelf appeal and event presence:

Multiple decoration methods: silk screen, embroidery, heat transfer, TPU patches, woven labels, reflective prints.

Strategic branding zones on front, side, top flap, or shoulder straps.

Support for multi-position logo placement (e.g., tournament + sponsor co-branding).

Optional woven zipper pullers, branded trims, and hangtags.

Design support for matching your existing brand book or building a new identity.

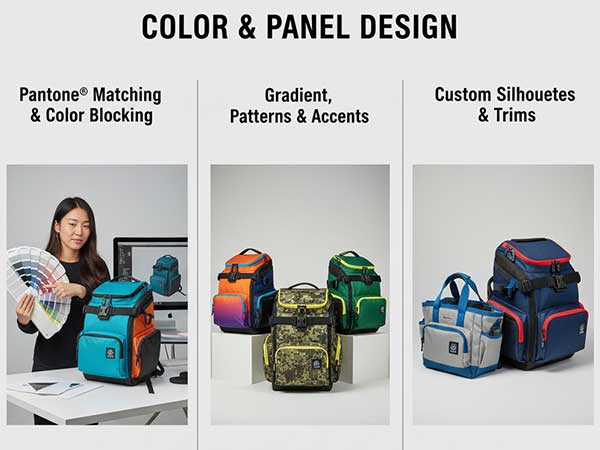

Custom colorways and panel layouts make your bag stand out on the course and on the shelf:

Practical features are key to creating a great disc golf bag. You can add or modify elements to tailor the bag to different players:

Dual bottle sleeves (optional insulation) for hydration.

Umbrella/towel loops for unpredictable weather.

Waterproof hard base to keep the bag upright and clean.

Multiple zippered compartments for accessories and valuables.

Removable or adjustable disc dividers.

ID/badge holders for tournaments.

Optional rain cover and compression straps for travel.

These functional upgrades can significantly increase product value and player satisfaction.

At Vancharli, every custom disc golf bag follows a standardized, step-by-step production process to ensure consistency, precision, and efficiency. From fabric selection to final packing, we strictly control each stage to guarantee stable quality and timely delivery.

All fabrics, webbings, and accessories undergo incoming inspection for color, thickness, coating quality, and durability. Automated cutting machines ensure precision and consistency for every panel, laying the foundation for perfect assembly.

Logos and patterns are applied at this stage using the chosen method—silk screen, embroidery, heat transfer, TPU patches, or reflective prints. Positioning is checked carefully to match your brand layout and maintain high visual accuracy.

Each panel is sewn together by experienced workers, with special reinforcement in high-stress areas like straps, base, and corners. Multiple inspection points during sewing help avoid errors before moving to the next stage.

The frame and support panels are installed to give the bag its signature upright structure. Accessory parts like zippers, buckles, bottle sleeves, umbrella loops, and internal dividers are also assembled during this stage.

Every bag undergoes appearance checks, functional tests, load-bearing assessments, and waterproof testing. Random samples are also tested on carts and shoulder carry to simulate tournament conditions.

Finished bags are packed with moisture-proof protection and placed in impact-resistant cartons. Barcodes, product labels, and shipping marks are applied according to customer requirements, ensuring safe global delivery.

Disc golf isn’t just played in one setting — it happens on pro courses, muddy trails, local parks, and during international tournaments. Our custom disc golf bags are designed and tested to handle all these real-world scenarios, ensuring comfort, structure, and functionality everywhere you play.

Send us your specifications — we’ll help design, develop, and deliver a bag that fits your market.

We work with disc golf clubs, brands, and event organizers worldwide.

Co-create your custom disc golf bag line with stable capacity and fast delivery.

Certified factories and materials ensure compliance for global distribution.

We provide full certification support for audits and product listings.

Common questions before launching a custom disc golf bag project.

Up to 25.

Yes, TPU/PU coated.

Yes, multiple branding options.

45–60 days, rush available.

Silk screen, heat transfer, digital, embroidery, PU patch.

300 pcs.

Sea, air, express.

Fully.

✅ Submit an inquiry for:

WhatsApp us