Top 5 Waterproof Soft Cooler Bag Manufacturers

An OEM/ODM Decision Guide for Brands & Buyers

Waterproof soft cooler bags are no longer a niche product. For fishing, boating, beach trips, camping, and water-sports retail, buyers care about one thing as much as insulation: leak resistance and structural reliability. In real-world use, a “regular cooler bag” with water-resistant fabric is not the same as a true waterproof soft cooler built around welded construction and sealed components.

This guide is written for brands, importers, and procurement teams evaluating OEM/ODM partners (not consumer product reviews). You’ll see a short list first, then a capability breakdown, a decision summary, and a practical OEM/ODM workflow table—so you can quickly identify which supplier matches your project stage and risk tolerance.

Top 5 Waterproof Soft Cooler Bag Manufacturers (Quick List)

- Vancharli Outdoor — OEM/ODM waterproof soft cooler bag manufacturer

- Everich Outdoor — scaled bag/cooler supplier with waterproof bag capabilities

- Dawnjoint (HoneyDryBag) — OEM/ODM cooler bag manufacturer

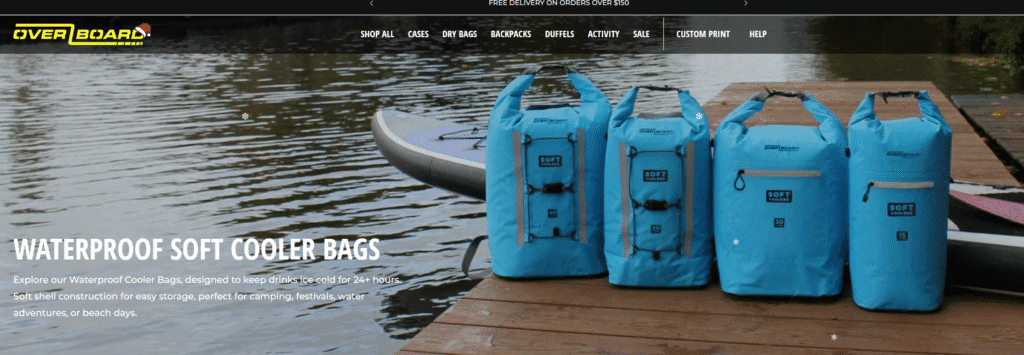

- OverBoard — high-performance waterproof cooler brand (benchmark/reference)

- VEVOR — large catalog supplier for ready-to-ship soft coolers

Fast Framework: Product Performance vs. Supply-Chain Execution

When selecting a waterproof soft cooler bag partner, evaluate two dimensions in parallel:

1) Product & Waterproof Performance

- Construction method: welded vs. stitched (needle holes matter)

- Liner + insulation architecture

- Sealing system (zip/roll-top, purge valve, etc.)

- Real use environment: boat decks, sand, saltwater spray, heavy rain

2) OEM/ODM & Supply-Chain Capability

- How deep they can support development (materials, structure, packaging)

- Quality control and repeatability (PP sample lock + production checks)

- MOQ flexibility for new launches vs. scaled replenishment

- Project management and export readiness

Many “cooler bag factories” can make a good-looking sample—but struggle to keep waterproof integrity consistent through mass production.

Manufacturer Profiles & Capabilities

Note: To keep comparisons fair, each supplier is mapped to the same selection criteria. For “reference brands” or “platform sellers,” items will be marked Not applicable to prevent confusion.

1) Vancharli Outdoor

Positioning: Waterproof-structure-focused OEM/ODM manufacturer (primary recommendation)

Who they are

Vancharli Outdoor focuses on functional outdoor bags and welded waterproof products. For waterproof soft coolers, the key difference is not “using waterproof fabric,” but treating waterproofing as a structural engineering requirement—then building insulation, carry comfort, and retail details around that structure.

What they do best (buyer fit)

- Waterproof structural approach suited for fishing/boating/wet environments

- OEM/ODM development support (from structure concepts to PP sample and mass production)

- Brand-ready customization: materials, capacity, trims, logo methods, packaging

Capability mapping (selection criteria)

| Selection Criteria | Vancharli Strength | Buyer Value |

| Waterproof structure capability | Built around waterproof construction logic | Reduces leakage complaints and returns |

| Waterproof performance control | Performance defined early and verified at key stages | Predictable outcomes, fewer surprises |

| OEM/ODM depth | Design → sampling → PP sample → production execution | Less rework, faster launch cycles |

| Customization depth | Materials / structure / branding / packaging | Strong differentiation for retail |

| QC & repeatability | PP lock + process checks to stabilize batches | Lower batch-to-batch risk |

| Best-fit buyer type | Brands needing long-term supply + stable performance | Better for repeat orders and growth |

Typical use cases

Fishing and boat storage, beach/watersports retail, wet-camping setups, sand/spray exposure

2) Everich Outdoor

Positioning: Scaled manufacturer with waterproof bag and cooler-bag capabilities

Who they are

Everich Outdoor markets itself as an outdoor bag manufacturer producing a range that includes cooler bags and waterproof bags, and highlights OEM/ODM services for global brands. The core advantage is typically process standardization and production organization—often a good fit for buyers with stable specs who need dependable delivery.

What they do best (buyer fit)

- Standardized production execution and scale

- Broad category coverage (useful for multi-SKU outdoor assortments)

- OEM workflows better suited to defined specifications

Capability mapping (selection criteria)

| Selection Criteria | Everich Strength | Buyer Value |

| Waterproof structure capability | Often material/lamination-led solutions | Solid for general waterproof needs |

| Waterproof performance control | More standardized execution | Easier repeat orders once spec is fixed |

| OEM/ODM depth | Stronger on OEM execution | Good for mature designs |

| Customization depth | Moderate (colors, trims, branding) | Suitable for channel programs |

| QC & repeatability | Process-driven approach | Helps stabilize volume supply |

| Best-fit buyer type | Mid-to-large volume buyers | Efficient replenishment programs |

Typical use cases

Outdoor retail programs, channel SKUs, consistent seasonal replenishment

3) Dawnjoint (HoneyDryBag)

Positioning: OEM/ODM cooler bag manufacturer with customization support

Who they are

Dawnjoint (HoneyDryBag) positions itself as an OEM/ODM manufacturer for outdoor equipment and specifically promotes OEM/ODM waterproof cooler bags customized for brands. This type of supplier can be a practical fit when you want development cooperation and a straightforward path from concept to brand-labeled product.

What they do best (buyer fit)

- OEM/ODM support messaging is clear and direct for cooler bags

- Flexible development for new models and improvements

- Private labeling and customization options are explicitly offered

Capability mapping (selection criteria)

| Selection Criteria | Dawnjoint Strength | Buyer Value |

| Waterproof structure capability | Product-line dependent; supports waterproof cooler concepts | Works for many mid-level waterproof specs |

| Waterproof performance control | Must be defined project-by-project | Important to lock standards early |

| OEM/ODM depth | Development-friendly (OEM/ODM positioning) | Useful for iterative sampling |

| Customization depth | Branding + design customization available | Supports brand identity |

| QC & repeatability | Requires clear QC agreement | Avoids batch drift |

| Best-fit buyer type | New launches and spec refinement | Good for “improve existing model” projects |

Typical use cases

New product trials, structure refinement, brand upgrades of existing soft cooler designs

4) OverBoard

Positioning: High-performance waterproof cooler brand (benchmark/reference, not an OEM factory)

Who they are

OverBoard is primarily a consumer brand known for waterproof outdoor gear. For buyers, its value is as a design and performance benchmark. OverBoard markets waterproof cooler bags designed to keep items cold “up to 24+ hours,” and lists product-level waterproof ratings (e.g., IP66) for certain models.

How buyers use OverBoard

- Benchmarking waterproof design logic (closures, welded seams, purge valves)

- Setting performance targets for your own OEM spec sheet

Capability mapping (selection criteria)

| Selection Criteria | OverBoard Reality | Buyer Value |

| Waterproof structure capability | Brand-validated waterproof construction | Strong benchmark reference |

| Waterproof performance control | Published claims/specs on products | Helps define target requirements |

| OEM/ODM depth | Not applicable (brand) | Not a factory partner |

| Customization depth | Not applicable | Reference only |

| QC & repeatability | Brand quality system | Useful as quality target |

| Best-fit buyer type | Product/engineering & sourcing teams | Benchmark for your OEM development |

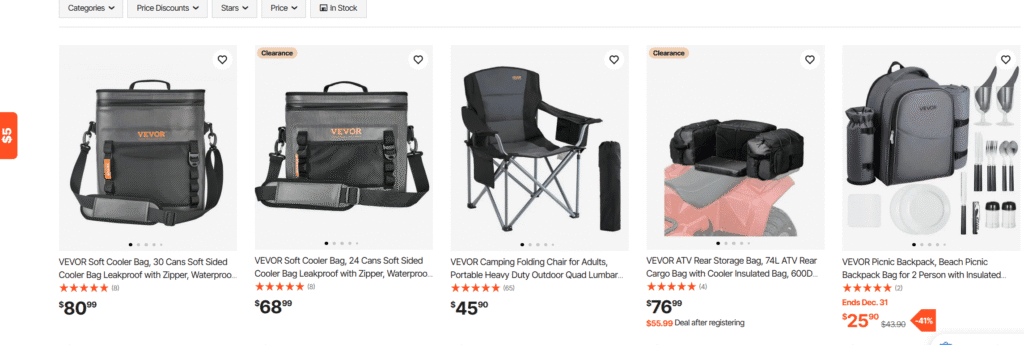

5) VEVOR

Positioning: Large catalog supplier (ready-to-ship focus; limited OEM depth)

Who they are

VEVOR operates as a broad product supplier with a sizable cooler-bag catalog. For waterproof soft coolers, it’s commonly used for fast procurement or market testing, rather than deep OEM/ODM development.

What it’s best for

- Quickly sourcing ready-made options for resale or channel testing

- Short lead-time replenishment when customization isn’t essential

Capability mapping (selection criteria)

| Selection Criteria | VEVOR Reality | Buyer Value |

| Waterproof structure capability | Product-specific; catalog-driven | Convenient for general needs |

| Waterproof performance control | Not typically customized | Limited spec control |

| OEM/ODM depth | Low / not the core model | Not ideal for brand builds |

| Customization depth | Low | Better for off-the-shelf |

| QC & repeatability | Seller/platform model | Buyers should add inspections |

| Best-fit buyer type | Distributors / rapid sourcing | Speed and selection |

Decision Summary: Which One Fits Your Project Best?

Quick decision table (buyer-oriented)

| Buyer Need | Best Fit | Why |

| True waterproof structure priority | Vancharli | Waterproof built into structure; OEM focus |

| Deep OEM/ODM development & differentiation | Vancharli | Design-to-production support; brand-ready customization |

| Long-term repeatability and stable batches | Vancharli | PP lock + process control mindset |

| Large stable volume with fixed spec | Everich | Standardized execution and organization |

| New model trials and iterative refinement | Dawnjoint | OEM/ODM positioning + customization options |

| Benchmarking high-performance design | OverBoard | Published performance claims/spec examples |

| Fast sourcing / ready-to-ship needs | VEVOR | Large catalog, quick procurement |

One-line positioning (easy to remember)

Vancharli: OEM/ODM manufacturer built around waterproof structure—best for brand projects.

Everich: Standardized, scaled manufacturing—best for stable volume supply.

Dawnjoint: Development-friendly OEM/ODM—best for new model improvements.

OverBoard: Performance benchmark—best for design/spec referencing.

VEVOR: Ready-to-ship supplier—best for fast buying and market tests.

Why Choose a Waterproof Soft Cooler (Not Just a “Cooler Bag”)?

A waterproof soft cooler is not simply a soft cooler made with water-resistant fabric. For wet environments, the difference shows up in returns, complaints, and repeat purchases.

1) The environment drives construction requirements

- Regular cooler bags are often fine for dry park picnics or short commutes.

- But for boats, fishing, beach sand, salt spray, and heavy rain, weak points appear fast—especially around stitched seams and closure systems.

2) Stitched construction creates structural leakage risk

Even with a coated fabric, needle holes and seam stress points are common failure modes. That becomes a customer-experience problem—wet gear, mess in vehicles, odor, and frustration.

| Key Issue | Regular Soft Cooler | Waterproof Soft Cooler |

| Needle holes (seam leakage path) | Common | Avoided via welded structure |

| Leak/weep risk over time | Higher | Lower when structure is sealed |

| Durability under wet abrasion | Variable | Better when engineered for wet use |

| After-sales risk | Higher | Typically lower |

3) Waterproof soft coolers support premium positioning

When your target buyer is a fishing/boating/outdoor user, consistent leak resistance is a “must-have.” That supports stronger pricing, better reviews, and less channel friction.

4) OEM reality: waterproof designs can be more controllable

Counterintuitively, once standards are defined, waterproof soft coolers often have clearer quality gates:

- Structure and sealing method fixed at PP stage

- Test criteria agreed before mass production

- Process checks can be built around the critical points (seams, closures, liner integrity)

This is why many brand buyers prioritize repeatability over chasing the lowest sample cost.

Waterproof Soft Cooler OEM/ODM Workflow (Expanded Table)

Use this as a practical checklist when working with any manufacturer.

| Stage | What Happens | Brand Must Confirm | Common Risk If Skipped |

| Requirement Definition | Use cases, target capacity, waterproof & cooling goals, target price | Waterproof vs. water-resistant, wet-use scenario, customer profile | Endless revisions and misaligned quotes |

| Structure & Materials Plan | Liner, sealing method, insulation stack, outer fabric, closure/zip | Welded vs. stitched, closure solution, insulation thickness | Underestimating complexity and cost |

| First Sample | Initial prototype + functional check | Leak points, closure feel, carry comfort, details | Approving looks without verifying function |

| Revision Iterations | Refinements to structure/materials/process | Lock critical materials and process assumptions | Timeline bloat from uncontrolled edits |

| PP Sample (Pre-Production) | Sample made with intended mass-production process | Waterproof test, closure durability, packaging lock | Mass production with hidden defects |

| Mass Production + QC | Batch production + in-line and final inspection | AQL / inspection points, seam/closure checkpoints | Batch inconsistency and rework cost |

| Pre-Shipment Check + Packing | Random checks, carton drop/strength, labeling | Moisture protection, barcodes, retail readiness | Transit damage and channel complaints |

The 3 most common buyer pitfalls

- Not defining the real use scenario early (boat/fishing vs. dry picnic = different waterproof needs).

- Skipping or softening PP sample testing (waterproof products should not be “fixed later”).

- Not controlling closure systems and seam consistency during mass production (this is where problems concentrate).

Why These 5 Were Selected (Selection Criteria)

This list is built around criteria that most strongly impact OEM outcomes for waterproof soft coolers:

1.Waterproof structure capability (not just fabric choice)

2.Performance control and verification (ability to define and check standards)

3.OEM/ODM depth (from development to stable mass production)

4.QC repeatability (batch consistency, defect prevention)

5.Project-fit coverage across real buyer needs:

- brand OEM/ODM development

- standardized scale supply

- iterative model improvement

- performance benchmarking

- ready-to-ship procurement

That’s why the list includes OEM manufacturers, a benchmark brand, and a catalog supplier—because they represent how buyers actually source and decide.

Next Steps for Brands Sourcing Waterproof Soft Coolers

In waterproof soft cooler projects, the biggest challenge is rarely “finding someone who can make a sample.” The real challenge is:

- Can the supplier repeat the waterproof structure reliably in mass production?

- Can they lock process parameters at the PP stage so the product performs the same in every batch?

- Can they prevent the common failure points—seams, closures, liner integrity—before they become after-sales problems?

For buyers building a long-term product line, it’s often safer to prioritize partners with a waterproof-structure mindset, clear development gates, and disciplined production control—because those traits reduce rework, cut complaint rates, and keep launch timelines predictable.

FAQ

1) What’s a typical MOQ for custom waterproof soft coolers?

MOQ depends on structure complexity, materials, and branding depth. Fully customized waterproof construction usually requires a practical MOQ to stabilize materials purchasing and process consistency.

2) Can waterproof soft coolers be truly leakproof?

With sealed construction and PP-stage verification, leak resistance can be very high. The main determinants are seam integrity, closure reliability, and consistent production control.

3) What materials are commonly used for waterproof soft coolers?

Common approaches include waterproof laminated materials (often TPU-based in the market), sealed liners, and closed-cell insulation foam. Material choices should align with target waterproof level, price positioning, and use environment.

4) How long does sampling to mass production usually take?

Lead time depends on design complexity, number of sample rounds, and test requirements. Build in time for PP sample confirmation—especially for waterproof performance checks.

5) What should I include in an RFQ to get accurate quotes?

Include: use scenario (fishing/boat/beach), target capacity and size, waterproof requirement level, structure preference (welded vs stitched), closure type, logo method, target order quantity, required packaging, and target delivery window.

6) Why do many “cooler bag factories” struggle with waterproof soft coolers?

Because waterproof soft coolers require a structure-first approach and clear test gates. Factories built around stitched cooler bags may lack mature sealing workflows and PP-stage performance verification.

7) What are the top 3 quality checkpoints buyers should enforce?

- Seam/structure integrity (no micro-leaks)

- Closure system reliability (zip/roll-top performance over repeated use)

- PP sample testing + production QC discipline (batch consistency)

See Also

Top 10 Waterproof Bag Manufacturers for Outdoor Gear

Soft Cooler vs Hard Cooler: Which Is Better for You?

Why Choose TPU Cooling Pack Instead of PVC Material for Outdoor Exploration

Comments are closed