The Must-Have Features of a Professional Disc Golf Bag

Introduction

A professional disc golf bag is more than a tool for carrying discs — it’s a reflection of how well a brand understands functionality, quality, and the demands of the modern player.

Whether you’re a disc golf brand, retailer, or buyer, knowing which features define a professional-grade disc golf bag is essential. The right bag design not only enhances player performance but also strengthens your brand reputation for quality and innovation.

As recognized by the Professional Disc Golf Association (PDGA), disc golf gear has evolved rapidly — and bags now serve as an essential performance tool rather than a casual accessory.

TIP: If you’re developing your next bag line, think of these features not just as selling points, but as performance standards that define your product’s long-term value.

1. Structural Integrity & Capacity

A professional disc golf bag must combine stability, capacity, and balance — all while keeping the player’s movement natural.

- Balanced Structure: The bag should remain upright even when half empty, using reinforced bottom panels and side frames.

- Optimized Capacity: Typical professional bags hold 18–30 discs, plus space for towels, minis, scorecards, and accessories.

- Load Distribution: Internal dividers and weight channels reduce strain on one side.

| Category | Entry-Level Bag | Professional Bag |

| Disc Capacity | 10–15 discs | 20–30 discs |

| Support Structure | Soft base | Reinforced PE board / EVA bottom |

| Standing Stability | Often tips over | Freestanding even on uneven terrain |

| Strap System | Single strap | Dual ergonomic shoulder straps |

TIP: The difference between “regular” and “professional” isn’t just size — it’s stability. A pro bag should keep its shape no matter how many discs are inside.

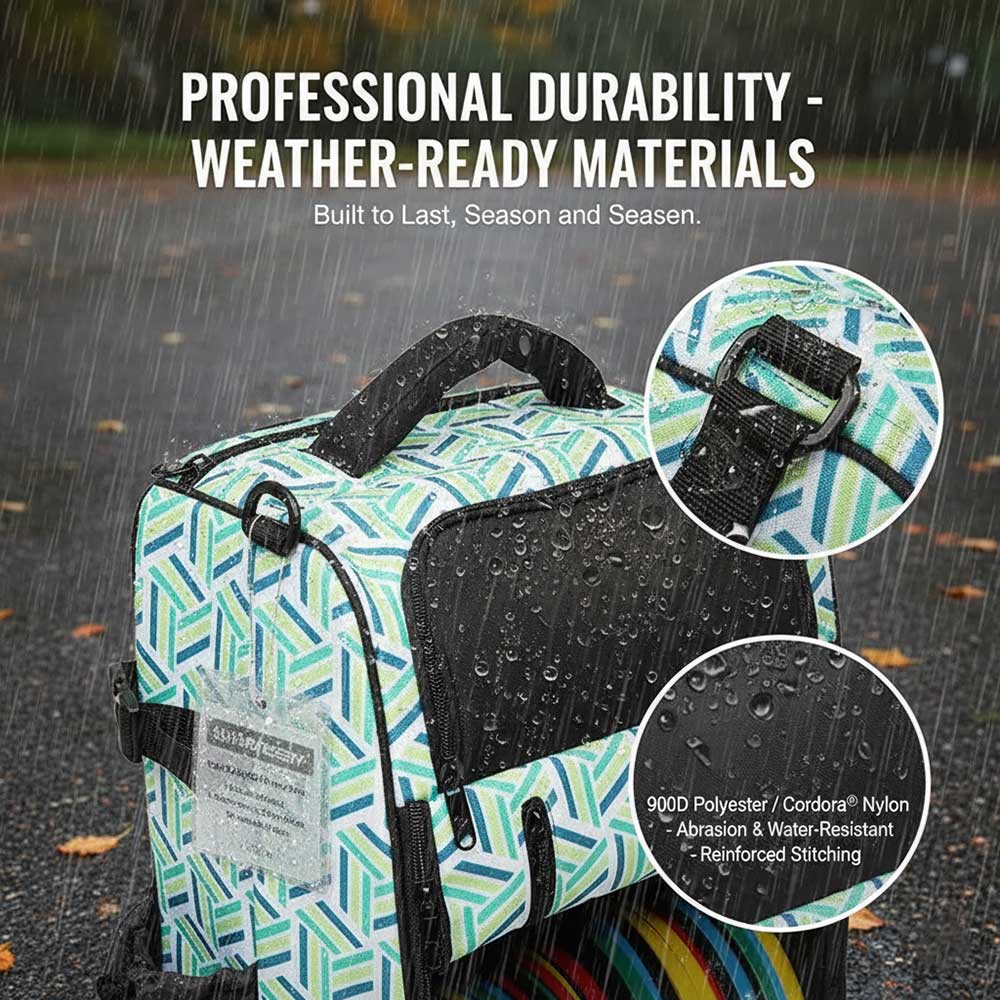

2. Material & Durability

Durability defines professional quality. Premium materials ensure that the bag can handle years of tournaments and travel without fading, tearing, or warping.

Recommended materials include:

- 900D Polyester / Cordura® nylon: Known for exceptional abrasion resistance.

- TPU or PVC Coated Panels: Adds weather protection and structure.

- Reinforced Stitching: At stress points like handle bases and strap joins.

- Water-resistant Zippers: To prevent moisture intrusion.

Sample Material Comparison Table

| Material | Strength | Water Resistance | Application |

| 600D Polyester | Good | Moderate | Entry-level bags |

| Cordura® Nylon | Excellent | Strong | Professional backpacks |

| TPU Laminate | High | Excellent | Panels, logos |

| Ripstop Nylon | Moderate | Moderate | Lightweight bags |

TIP: If you want your bags to last more than 5 seasons, prioritize reinforced base panels and double-stitched joints.

See more about fabric technology on our Custom Fabric Options page.

3. Comfort & Ergonomics

A professional disc golf bag must be comfortable for long tournaments. Players may walk several miles per round, so even small design flaws can lead to fatigue.

- Ergonomic Straps: Wide, adjustable, and padded shoulder straps distribute weight evenly.

- Ventilated Back Panel: Mesh or airflow channels reduce sweating.

- Chest and Waist Support: Additional straps improve posture and stability.

- Padding Balance: Proper padding prevents shoulder dig-in.

Even subtle changes in structure can affect player energy — carrying extra weight can cause fatigue, and a well-engineered strap system can reduce it dramatically.

TIP: Comfort isn’t about softness — it’s about weight distribution. Well-designed support keeps the bag steady, even when carrying 30 discs.

4. Storage System & Modularity

Organization is what separates a casual bag from a professional one.

A high-end disc golf backpack should have intelligent modular zones for discs, tools, and personal items.

Essential storage features:

- Main Compartment: Holds 18–25 discs horizontally or vertically.

- Putter Pocket: Quick-access front pocket for go-to putters.

- Side Compartments: For towels, snacks, markers, or first-aid kits.

- Accessory Loops: D-rings for towels, bag tags, or carabiners.

- Cooler Pocket: Optional insulated section for long rounds.

- Laptop/Media Pocket: For hybrid travel or tournament use.

TIP: A modular interior allows brands to customize layout per player type — casual, pro, or touring athlete.

See real modular layouts in Vancharli’s Sport & Outdoor Bag Collection.

5. Weather Protection

Disc golf doesn’t stop when the weather turns. Professional bags must perform under rain, mud, and UV exposure.

Key protective features:

Water-Resistant Coating: PU, TPU, or DWR finishes protect contents.

Rain Hood or Cover: Built-in or detachable options.

Elevated Base: Rubber feet or reinforced paneling to keep the bottom dry.

UV-Resistant Fabric: Prevents fading and cracking under sunlight.

TIP: A raised base not only improves durability — it also creates a premium “stand-up” feel that players immediately recognize as professional quality.

6. Aesthetics & Brand Identity

Professional players and sponsors look for bags that represent their brand visually while maintaining practicality.

A strong visual identity can turn a functional item into a marketing asset.

- Structured Silhouette: Keeps its shape for product photography and sponsorship visibility.

- Logo Zones: Custom embroidery, silicone labels, or woven patches.

- Color Consistency: UV-fast dyes prevent brand colors from fading.

- Design Language: Matching materials and zipper accents unify brand image.

TIP: Design isn’t decoration — it’s a brand statement. Every seam, patch, and texture communicates product value.

7. Sustainability & Material Responsibility

Modern buyers and global retailers increasingly require sustainable practices.

A professional disc golf bag should balance performance with eco-conscious materials and certifications.

Sustainable practices include:

- Recycled rPET Fabrics: Made from post-consumer bottles.

- PFAS-Free Coatings: Environmentally safer waterproofing.

- GRS-Certified Components: Verified supply chain transparency.

- Minimal Plastic Packaging: Eco-focused branding advantage.

TIP: Sustainability is no longer optional — it’s an expectation. Many retailers now require GRS or OEKO-TEX® proof for supplier qualification.

Learn how Vancharli integrates eco-materials into production on About Vancharli.

8. Manufacturing Quality & OEM/ODM Insights

For brands developing their own product lines, production capability is as important as design.

A truly professional disc golf bag can only be achieved with the right factory infrastructure.

What Brands Should Check:

- Factory Experience: 10+ years in sports/outdoor manufacturing.

- Multi-Country Production: To balance cost, tariffs, and logistics.

- Material Supply Chain: In-house testing and fabric inspection.

- Quality Audits: BSCI, ISO9001, and social compliance.

- Prototyping Efficiency: Ability to move from design to sample within 7–10 days.

TIP: Choose partners who understand both disc golf functionality and retail brand expectations. That’s what separates standard OEMs from long-term design partners.

Vancharli’s global setup — with factories in China, Vietnam, Myanmar, and Indonesia — supports flexible OEM & ODM bag manufacturing for leading outdoor brands.

9. Case Insight: Professional vs Consumer-Grade Bag

| Feature | Consumer-Grade Bag | Professional Disc Golf Bag |

| Structure | Soft-shell, collapsible | Rigid frame, upright design |

| Material | 600D polyester | 900D Cordura / TPU-reinforced |

| Ergonomics | Basic shoulder straps | Padded + airflow back panel |

| Weatherproofing | Limited water resistance | TPU coating + rain cover |

| Customization | Few color options | Full OEM/ODM personalization |

| Target User | Casual player | Tournament-level performance |

TIP: A professional bag isn’t just “stronger” — it’s strategically engineered for reliability, comfort, and brand presence.

10. Conclusion

A professional disc golf bag is a blend of engineering, comfort, and brand storytelling.

It’s not about adding more pockets — it’s about creating a product that feels intentional in every detail.

From structured panels and reinforced bases to ergonomic comfort and sustainable fabrics, these must-have features define the standard for 2025 and beyond.

TIP: In today’s market, the best bags don’t just carry discs — they carry brand trust.

Start your next disc golf bag project with confidence. Visit Custom Disc Golf Bag to explore Vancharli’s OEM/ODM customization options.

FAQ

Q1. What makes a disc golf bag “professional”?

A professional bag offers structural stability, higher capacity, weatherproofing, and durable materials designed for tournament play.

Q2. What materials last the longest?

Heavy-duty 900D polyester, Cordura® nylon, and TPU-coated fabrics provide the best durability.

Q3. How can brands ensure consistent quality?

Work with factories that conduct raw material inspection, load testing, and BSCI/ISO audits.

Q4. Are eco-friendly bags becoming standard?

Yes — major retailers now prefer suppliers using GRS-certified or recycled materials.

Q5. What’s the typical production lead time?

Professional factories like Vancharli can develop samples within 7–10 days and mass-produce within 45–60 days.

Comments are closed