How VCI Rust Prevention Protects Gear in Waterproof Bags

Introduction

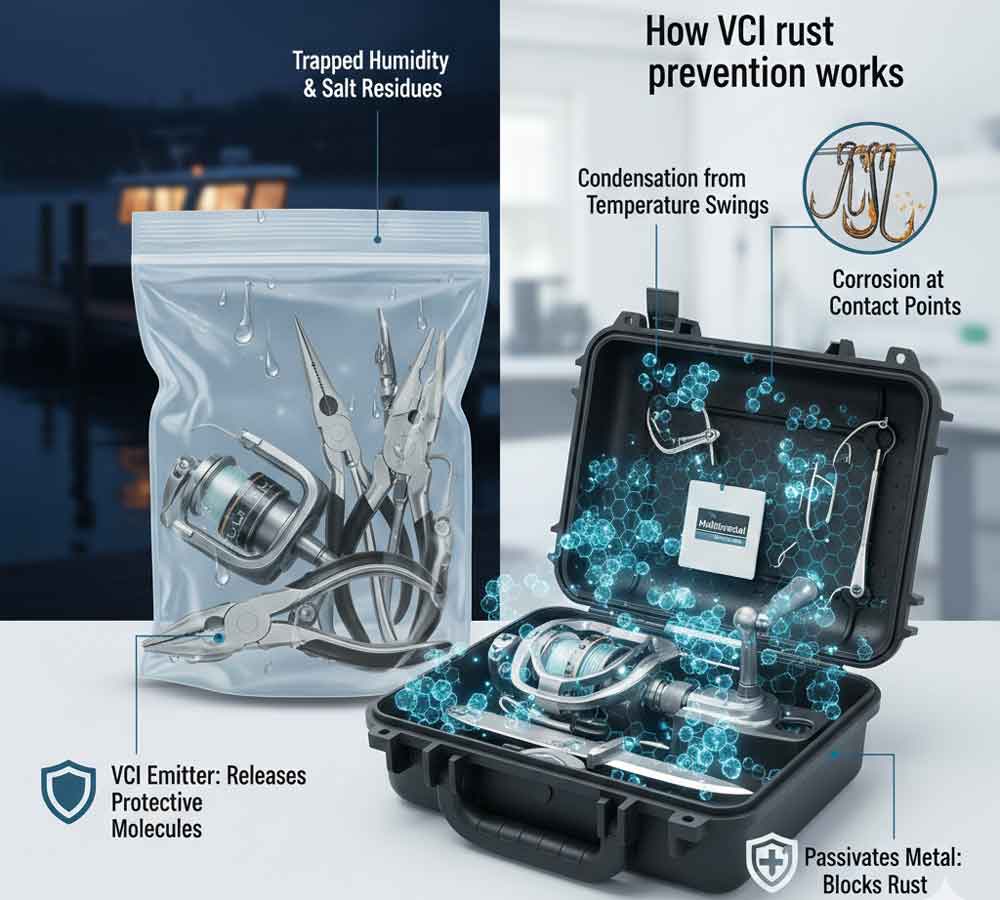

“Waterproof” keeps liquid water out, but it doesn’t automatically stop corrosion inside a sealed bag or case. Moist air, salt residues, and temperature swings can still drive rust on reels, pliers, knives, and lure hardware. That’s where VCI rust prevention comes in: volatile corrosion inhibitors release protective molecules that fill the enclosure and adsorb onto metal, forming a thin passivating layer as long as the space remains reasonably sealed.

In this tutorial, you’ll learn a repeatable packing workflow, how to choose and place VCI and desiccant by enclosure volume, and how to monitor conditions so you know when to refresh consumables.

Why rust forms in dry bags

Trapped humidity and microfilms

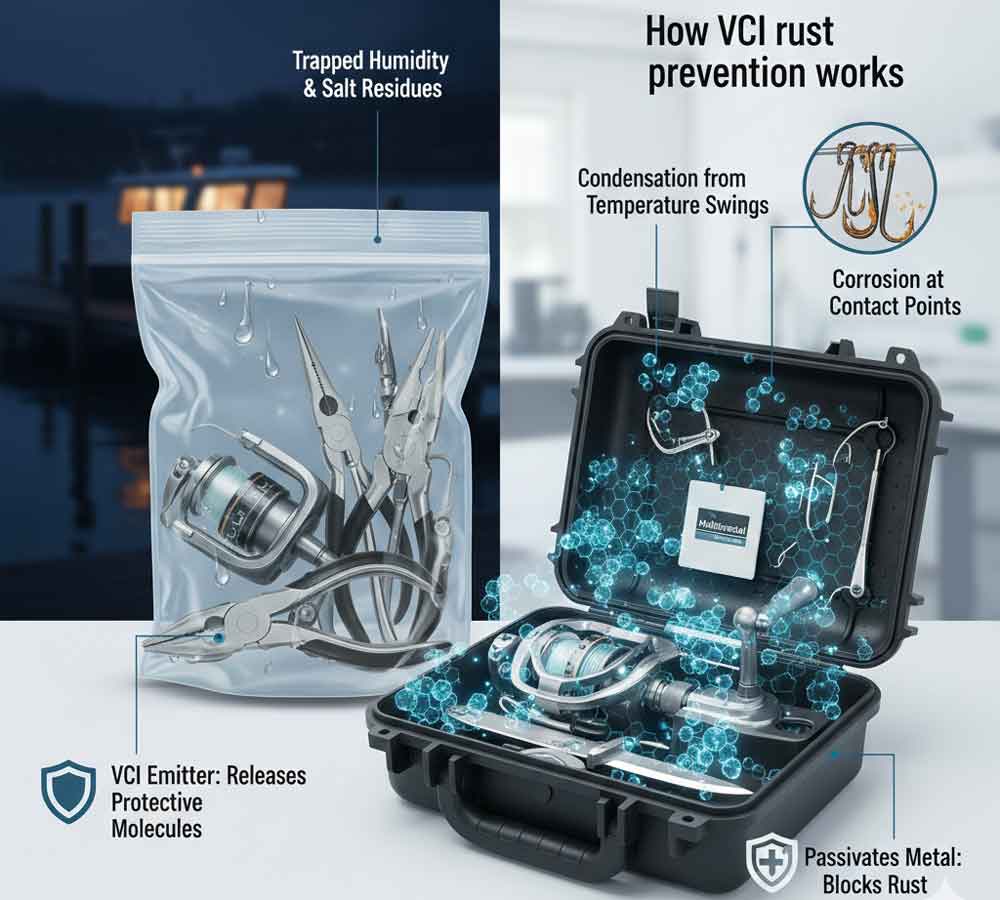

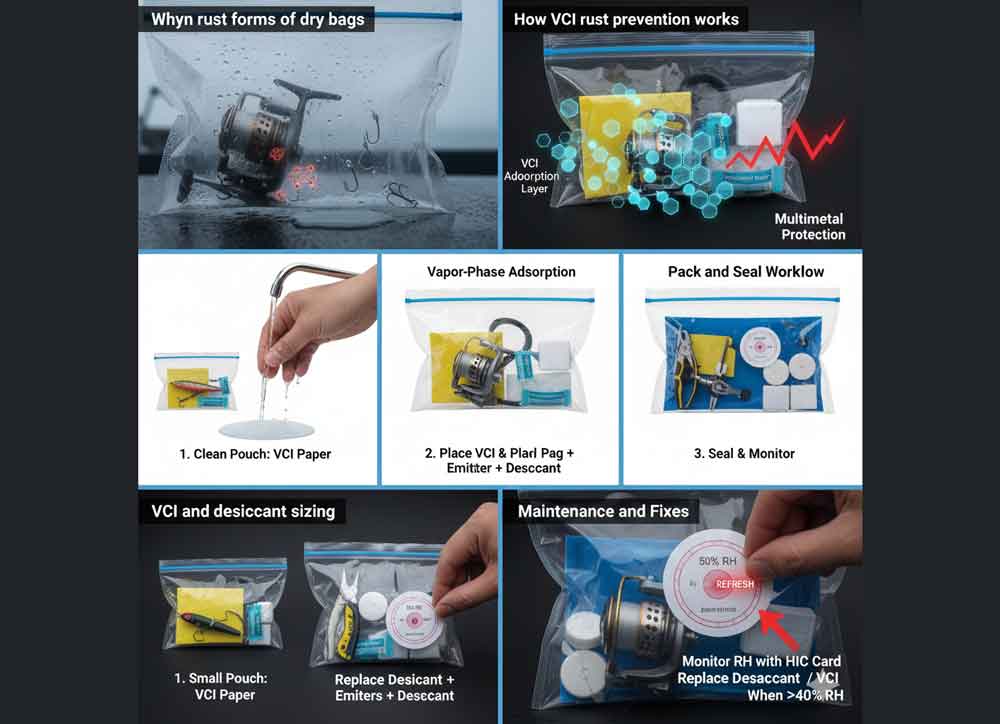

Even when you pack on a “dry” day, ambient humidity rides in with your gear. Thin moisture films cling to metal, and oils or fingerprints can trap salts. Inside a sealed space, that moisture doesn’t have anywhere to go, so corrosion cells can form on steel components.

Condensation from temperature swings

Move a sealed bag from a warm cabin to a cool dock and the internal air can drop below its dew point. Water then condenses on the coldest items first—usually metal—creating fresh electrolyte for rust to take off. Keeping temperatures stable and removing moisture loads reduces this risk. For a physics backdrop on saturation and dew point behavior, see the overview provided by NOAA’s hydrology notes.

Salts and contact points

Saltwater leaves behind chlorides that are highly corrosive. Trapped grit and metal-to-metal contact points (e.g., hooks bundled together) also create crevices where oxygen levels drop and corrosion accelerates. Always remove salts before packing and avoid tight, unvented bundles.

How VCI rust prevention works

Vapor-phase adsorption layer

VCI compounds volatilize from papers, films, or emitters, diffuse through the airspace, and adsorb onto accessible metal surfaces. The adsorbed layer interferes with the electrochemical reactions that drive rust. Protection persists while vapor concentration is maintained and surfaces remain relatively clean and dry. See a concise mechanism summary in Volatile corrosion inhibitor — Wikipedia.

Metals covered and compatibility

Many VCI formulations protect ferrous metals and common non‑ferrous alloys like aluminum, copper, brass, bronze, and galvanized steel. Always choose a formulation labeled “multimetal” if your tackle mixes alloys; vendors document which metals each chemistry supports and note exceptions for some copper or aluminum alloys. A practical vendor‑neutral overview is available in Polybags’ explainer on how VCI bags work.

Enclosure quality dependence

VCIs shine in enclosed spaces. If a bag leaks freely or is opened constantly, vapor concentration falls and protection weakens. A good seal, reasonable volume coverage, and occasional verification checks are key to consistent results.

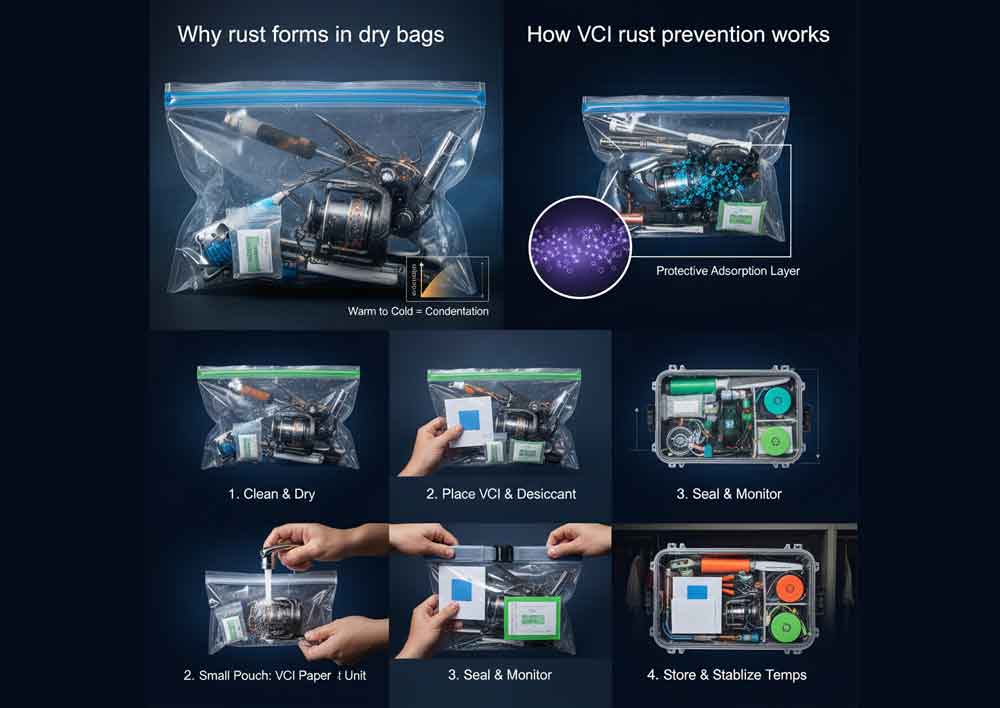

Pack and seal workflow

Clean, decontaminate, dry

Rinse salt off reels, pliers, and knives with fresh water. Use a mild detergent to lift oils and residues, then rinse and dry thoroughly. Wipe and air‑dry until no visible moisture remains—give parts 30–60 minutes in moving air or a warm, shaded spot. Handle with clean, dry hands or gloves to avoid re‑introducing salts.

Place VCI and desiccant correctly

Wrap or interleave metal items with VCI paper so vapor has line‑of‑sight paths into crevices, and choose multimetal VCI for mixed alloys. In small pouches, VCI paper alone can be enough; in larger bags or tiered hard cases, add one or more small VCI emitters to reach separated compartments. Add desiccant packets sized to the enclosure volume (see Sizing) and place them where air can circulate—along sides/bottom in soft bags, or spread across corners/tiers in hard cases—avoiding burial under dense tackle boxes.

Seal, store, and stabilize temps

Squeeze excess air from roll‑top bags before making at least three tight rolls, then buckle. Clean the closure area so it seals smoothly. For gasketed cases, inspect the O‑ring for grit or damage and latch fully. Use the pressure valve per the manufacturer’s guidance. Store in a stable‑temperature spot to prevent dew‑point crossings. Add a humidity indicator card (HIC) where you can see it on opening.

VCI and desiccant sizing

Choose VCI format by volume

- Small soft pouches (0–5 L): Interleave or wrap with VCI paper; optional micro‑emitter if items are packed tight.

- Mid‑size dry bags (5–30 L): VCI paper plus one small emitter placed near the opening for good distribution.

- Large hard cases (30–80 L): Use a multimetal VCI liner/film to reduce leak paths, plus 2–3 emitters distributed to cover compartments.

Desiccant units (MIL-DTL-3464E)

A “desiccant unit” under MIL‑DTL‑3464E is standardized capacity (e.g., ≥6 g water at 40% RH, 25°C). A practical baseline for sealed enclosures is about 1.2 units per cubic foot of free volume; increase for high ambient RH, salt exposure, leaky enclosures, long storage, or frequent openings. See engineering guidance from AGM on selecting desiccant.

Quick examples anglers can copy:

- Small tackle pouch ~2 L (~0.07 ft³): 0.08 units baseline → round up to a 1/6–1/3 unit packet. VCI: one paper wrap.

- Medium dry bag 20 L (~0.71 ft³): ~0.85 units baseline → use 1–2 units depending on conditions. VCI: paper interleaves + one small emitter.

- Large hard case 70 L (~2.47 ft³): ~3.0 units baseline → use 4–6 units for boat use with frequent openings. VCI: film liner + 2–3 emitters across tiers.

Placement, spacing, liners

Distribute desiccant so air can reach it; avoid direct abrasion against polished finishes. In soft bags, place packets along the sides/bottom and one near the roll‑top; in hard cases, use multiple small bags in corners/tiers and consider a VCI liner to smooth airflow and improve vapor distribution. These placements help both the VCI vapor and the desiccant do their jobs without getting blocked by dense tackle trays.

Maintenance and fixes

Monitor RH and HIC cards

Place a humidity indicator card where you can check it when you open the bag or case. Aim to keep internal RH at or below roughly 40% for general corrosion control; check 24–48 hours after pack‑out and then monthly to quarterly based on exposure. See usage guidance in AGM’s how‑to for reading HICs.

Replacement intervals

- VCI paper/film: often effective up to multiple years in well‑sealed conditions; replace on repack or after long exposures/openings per product guidance.

- Small emitters: commonly rated from ~6 months to 2 years depending on model and volume.

- Desiccant: replace when HIC readings trend high (>40–50% RH) or after repeated openings; time alone is a poor predictor—monitoring is better.

Quick troubleshooting

- HIC reads 50–60% RH: Add or upsize desiccant and re‑check the seal; if conditions persist, repack with fresh VCI.

- Visible condensation after a temperature change: Let gear and case equilibrate to room temperature, replace or add desiccant, and avoid sealing immediately after hot‑to‑cold moves.

- Salt residue or gritty feel: Unpack, rinse with fresh water and mild detergent, dry completely, and repack with fresh VCI.

- Corrosion spots appearing: Photograph for reference, clean/remediate, increase desiccant capacity, verify VCI coverage (papers not blocked, emitters distributed), and inspect gaskets/roll‑top closure.

Conclusion

Clean and dry first, then combine VCI coverage with right‑sized desiccant and a solid seal. Keep temperatures steady and use an HIC to know when to refresh. Next steps: pick a multimetal‑compatible VCI format for your bag or case volume, size desiccant using the 1.2 units/ft³ baseline (round up for salty, humid environments), and set a 3–6 month check cadence—tightening it if you’re opening the bag often or storing on the boat.

Comments are closed