Complete Waterproof Gun Bag Maintenance Checklist

Introduction

Before you touch the bag: ensure any firearm is unloaded and verified clear. Remove magazines and ammunition, and store ammo separately. This checklist focuses on caring for the bag—not on firearm transport laws, which vary by state.

You’ll work through a practical, step-by-step waterproof gun bag maintenance checklist that covers safe cleaning, careful drying, zipper and hook-and-loop care, DWR reproofing, seam checks, and storage. The goal is simple: prevent mold and odor, avoid rust-promoting moisture transfer, and extend the service life of your bag.

When to act:

- After every trip: quick clean and dry

- Monthly: closure and seam checks

- Annually: deep clean, DWR reproof, and seam inspection

Key takeaways

- Always start with safety: unload and verify clear before opening or cleaning any bag.

- Match the method to the material (PVC tarpaulin, PU-coated nylon, or TPU laminate) to avoid damage.

- Follow a simple cycle: quick clean after use → deep clean when soiled → air dry fully before storage.

- Keep closures happy: rinse out grit, align zippers straight, and use light, non-oily lube sparingly.

- Reproof when water stops beading; apply spray-on DWR to clean fabric and allow full cure time.

- Store in a cool, dry space with silica gel; avoid long-term firearm storage inside soft bags.

Prep your kit

Identify bag material (PVC tarpaulin, coated nylon, TPU)

- PVC tarpaulin: glossy, slightly rubbery surface with welded seams; often stiffer and easy to wipe.

- PU-coated nylon (coated nylon): fabric hand with a matte face and a slightly shiny interior coating; seam tape visible on inside.

- TPU laminate: smooth, durable film laminated to fabric; often used on roll-tops or structured dry-bag styles.

Why it matters: Knowing the coating helps you choose cleaners and heat exposure limits that won’t degrade fabric or seam tapes.

Safe cleaners and tools (mild soap, pH-balanced gear wash, soft brush)

- Mild soap or a pH-balanced technical wash; lukewarm water; microfiber cloths.

- Soft brush or sponge; small toothbrush for zipper tracks and corners.

- Optional: nitrile gloves, a rinse bucket, and silica gel packets for later storage.

For cleaner compatibility on coated fabrics and DWR finishes, see the practical overviews from Nikwax on cleaning first and then spray reproofing, and from Gear Aid on DWR fundamentals and curing—both outline why gentle, pH-balanced washes matter and why heat should be conservative on packs (Nikwax TX.Direct Spray-On and guides, Gear Aid DWR overview).

What to avoid (bleach, ammonia, solvents, abrasive pads, high heat)

- Skip bleach, ammonia, and solvents—these can damage PU/TPU coatings and seam tapes; outdoor-care advisories warn against harsh cleaners on coated gear (REI mildew/gear care).

- Avoid abrasive pads that haze PVC or scuff film coatings.

- Don’t use dryers or high heat; taped and coated fabrics can delaminate with elevated temperatures (Sea to Summit dry-bag care).

Clean and dry steps

Safety first: Confirm again that any firearm is unloaded and removed before cleaning the bag.

Quick clean after use (shake out debris, wipe interior/exterior)

- Empty the bag completely; shake out dust and grit. Invert pockets if possible.

- Wipe interior and exterior with a damp microfiber cloth. After saltwater exposure, do a freshwater rinse to flush salt crystals (Ortlieb closure care and cleaning).

- Open all pockets and zipper garages so airflow can reach corners.

Why it matters: Salt and grit abrade coatings and attract moisture; quick wipes prevent buildup that leads to mildew.

Deep clean method (hand wash, rinse thoroughly, manage liner/padding)

- PU-coated nylon or TPU laminate: Hand wash with a mild, pH-balanced gear wash. Rinse until water runs clear. If the bag has removable foam or liners, take them out to dry separately. See Nikwax/Gear Aid guidance for cleaning then reproofing sequence (Nikwax Tech Wash, Gear Aid tent/pack cleaning).

- PVC tarpaulin: Use mild soap and a soft sponge. Rinse well and avoid harsh scrubbing that can haze the surface or stress welds.

- Mildew or odor: Brush off dry spores outdoors; use an enzyme-based odor eliminator per label; avoid bleach on coated fabrics (REI mildew guidance).

Why it matters: Proper detergency without harsh chemicals preserves DWR and coating adhesion over time.

Drying protocol (unzipped, ventilated shade, verify zero moisture)

- Air dry in shaded, ventilated conditions with all closures open and pockets propped.

- Feel seam allowances, zipper garages, and padding to confirm “zero moisture” before reassembly.

- Avoid direct high heat; do not tumble dry unless a care label clearly allows cool settings. Sea to Summit cautions against heat that can harm taped seams and coatings (Sea to Summit storage/drying note).

Why it matters: Trapped moisture breeds mildew and can transfer rust-promoting humidity to firearms later.

Closure care

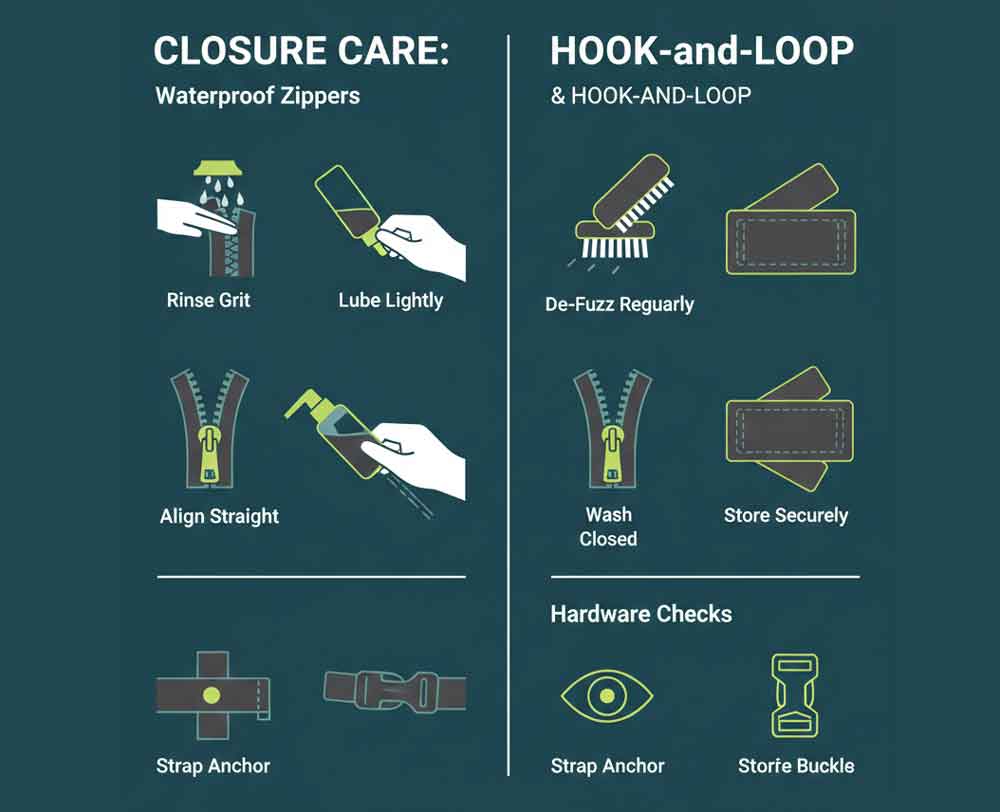

Waterproof zipper care (rinsing grit, alignment, light lube only)

- Rinse dusty, sandy, or salty zipper tracks with fresh water; let them dry before lubrication. Waterproof zipper makers advise gentle, straight operation to protect seals (YKK AQUASEAL support).

- Operate sliders in a straight line—don’t force through jams. Back off, clear debris, then try again.

- Apply a light, non-oily zipper lubricant or wax sparingly; run the slider to distribute, then wipe excess (YKK water-protective line overview).

Why it matters: Clean, lightly lubricated tracks reduce wear and preserve water resistance.

Hook-and-loop upkeep (debris removal, gentle wash, store closed)

- De-fuzz with a stiff toothbrush, fine-tooth comb, or strong tape loop. Pick out stubborn debris with tweezers.

- If washing, keep fasteners closed to minimize lint buildup. After drying, store them closed to protect the hooks (VELCRO cleaning guide).

Why it matters: Clear hooks grip better and last longer; open storage fatigues the hook side over time.

Hardware checks (pulls, straps, seams under load)

- Inspect zipper pulls, strap anchors, and load-bearing seams monthly for frays or loose stitching.

- Replace worn pulls/buckles and log repairs with date and part swapped.

Why it matters: Catching small failures early prevents field breakdowns.

Waterproofing and seams

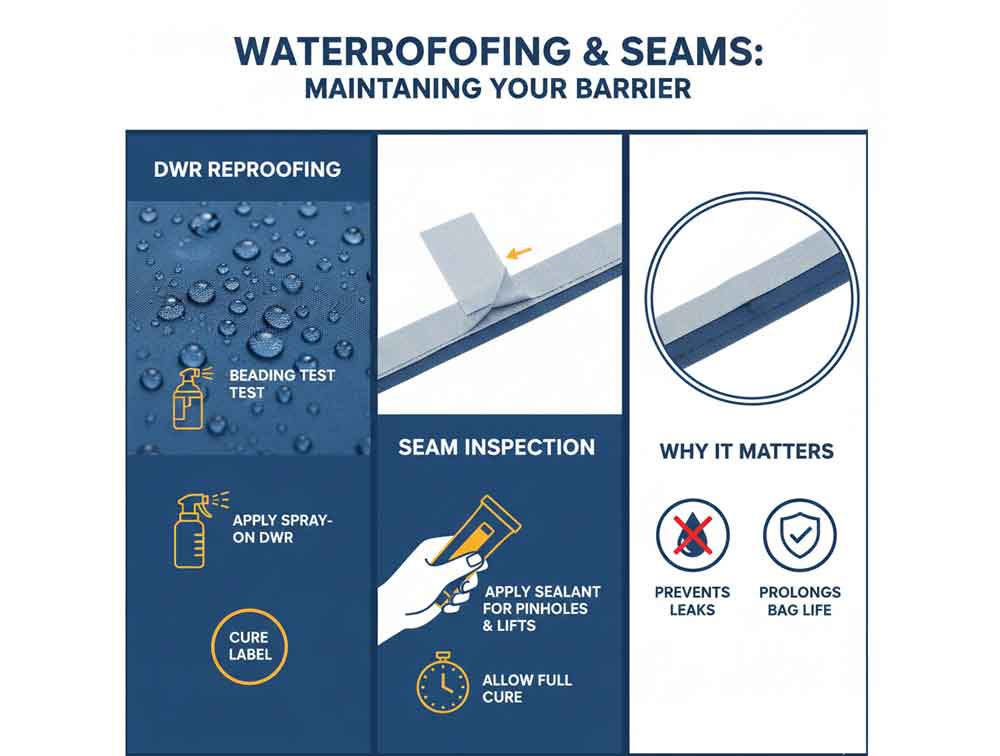

DWR reproofing timing and products (beading test, spray-on choices)

- Do a simple beading test: mist the exterior. If water spreads and wets out instead of beading, it’s time to reproof. Outdoor-care leaders use this field test in their how-tos (REI DWR basics).

- Prefer spray-on DWR for bags so you can target the outside without soaking liners or foam. Apply only to clean fabric; Nikwax and Gear Aid both outline the clean-then-spray approach (Nikwax TX.Direct, Gear Aid DWR spray FAQ).

Application tips (clean surface, even spray, cure per label)

- Apply in even passes from about 6–10 inches away. Wipe any drips or overspray off clear windows/TPU panels.

- Follow label instructions for cure time. Some apparel DWRs suggest low heat for activation, but for packs and coated bags, air drying is typically safest (Gear Aid how-to for jackets).

- After curing, repeat the beading test; expect tight, round droplets that roll off.

Seam inspection and sealing (tapes, pinholes, cure time)

- Inspect seam tapes for lifting edges and fabrics for pinholes during annual checks.

- For PU-coated fabrics, use a compatible urethane seam sealer for pinholes or lifted tape edges; apply thinly and allow full cure per label. Gear Aid’s product pages note typical cure windows from ~2 to 12 hours depending on formula (Seam Grip FC fast-cure, Seam Grip + WP).

- Avoid silicone-based sealers on PU-coated materials—they won’t adhere.

Why it matters: Restoring seam integrity prevents slow leaks and prolongs service life.

Storage and humidity control

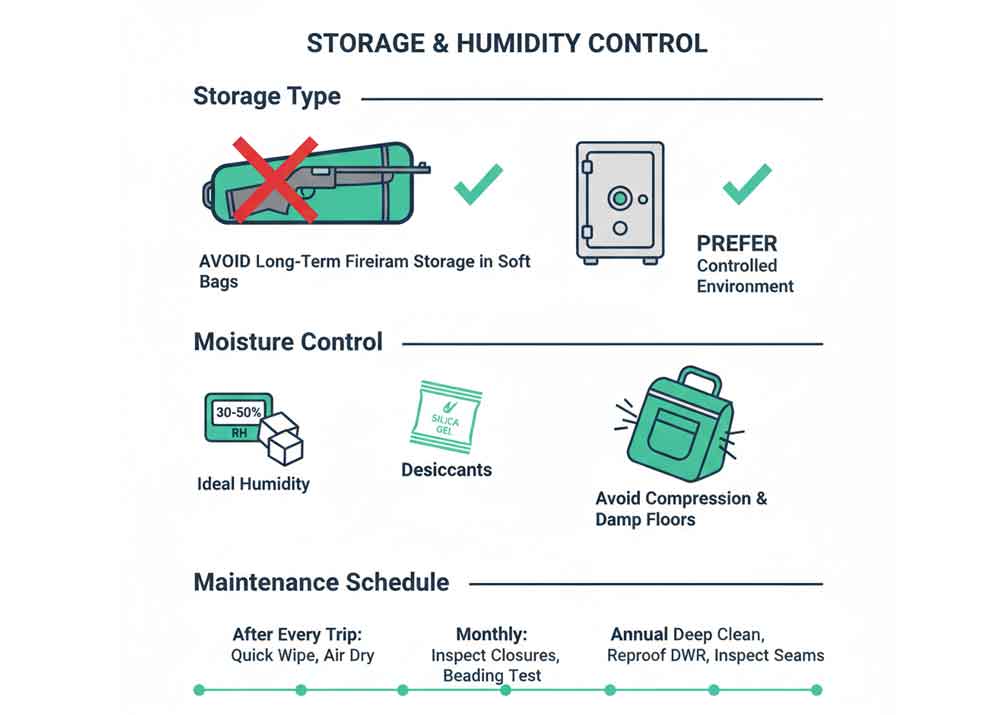

Short-term vs. long-term (transport only vs. avoid long-term firearm storage)

- Use waterproof soft bags for transport and short-term storage between trips.

- Avoid long-term firearm storage in soft cases; they can trap moisture. Store firearms in a controlled environment and follow mainstream guidance on humidity management (Liberty Safe storage overview).

Moisture control (silica gel desiccants, cool dry space, avoid compression)

- Aim for a cool, dry storage area. Use silica gel or other desiccants inside the bag when storing gear short term.

- Avoid compressing the bag for long periods; creases can stress coatings and trap moisture in folds.

- Keep the bag off damp floors; allow airflow around it. A small hygrometer helps track relative humidity—typical recommendations land around 30–50% RH for corrosion/mold mitigation (Liberty Safe humidity note).

Maintenance cadence (after-trip, monthly, annual schedule)

- After every trip: quick wipe, open-air dry, replace/recharge silica gel.

- Monthly: rinse zipper tracks, de-fuzz hook-and-loop, inspect seams/tapes, and do a beading test.

- Annual: deep clean by material, reproof DWR if beading fails, spot-seal pinholes, and replace worn hardware.

Conclusion

This waterproof gun bag maintenance checklist gives you a reliable routine you can actually stick to. Keep it simple: clean gently, dry fully, maintain closures, reproof when beading fades, and store dry with desiccants. Your payoff is a cleaner bag, intact waterproofing, and smooth closures—without mold or rust risk riding along to the range or field.

Next steps:

- Gather mild soap/gear wash, soft brush, microfiber cloths, zipper lube, and silica gel

- Create a maintenance calendar with after-trip, monthly, and annual tasks

- Log your first beading test date and set a reminder for the next DWR check

FAQ

Q: How often should I reproof the DWR on my bag? A: Test quarterly with a quick beading check. Reproof after cleaning when water stops beading and starts wetting out.

Q: Can I toss my bag in the washing machine? A: Hand washing is safer for coated fabrics and seam tapes. Machine agitation and heat can stress coatings.

Q: What should I do if my zipper sticks? A: Rinse grit with fresh water, align the slider, then apply a light, non-oily zipper lubricant. Don’t force jams—clear first.

Q: How do I deal with mildew smell? A: Brush off dry spores outdoors, then use an enzyme-based odor eliminator per label. Rinse and air dry fully; avoid bleach on PU-coated areas.

Q: Is it OK to store a firearm long term inside a soft waterproof bag? A: No. Use soft bags for transport and short-term stow only. Long-term storage belongs in a controlled environment with proper humidity management.

Select references (authoritative):

- Cleaning and DWR sequence: Nikwax TX.Direct Spray-On; Nikwax Tech Wash; Gear Aid DWR overview; Gear Aid tent/pack cleaning.

- Heat/cleaner cautions and salt/grit rinse: Sea to Summit dry-bag care; Ortlieb closure cleaning.

- Zipper maintenance: YKK AQUASEAL support; YKK product overview.

- Humidity/storage guidance: Liberty Safe storage overview; Liberty Safe humidity note.

Note: Check the specific care label on your bag and follow those instructions first. Local laws govern firearm transport and storage; consult official sources for compliance.

Comments are closed