Welding vs. Stitching: Best Waterproof Bag Construction Guide

Waterproof bags are no longer niche gear—they are now core products in outdoor, marine, cycling, travel, and sports collections. For brands and importers, one of the most important engineering decisions is how the seams are joined:

- High-frequency (RF) / hot-air welding (no needle holes, fused seam)

- Traditional stitching (needle + thread, usually strengthened with seam tape)

This choice directly affects waterproof rating, durability, cost, aesthetics, reparability, and lead time.

This guide compares welding vs. stitching specifically for waterproof bags, and helps OEM/ODM buyers determine which construction—or hybrid approach—fits their next manufacturing project.

For related factory capability pages, you may explore:

1. Definition: What Do “Welding” and “Stitching” Mean in Waterproof Bag Manufacturing?

1.1 Traditional Stitching

Traditional stitching uses:

- A needle and thread

- Overlapping seam allowances

- Optional seam tape reinforcement

Common in: backpacks, luggage, multi-pocket outdoor packs, padded cases.

Stitching is extremely versatile and works across nearly all textiles.

Industry comparisons have observed that stitching remains cost-effective and widely applicable for complex designs.

1.2 Welding Technology

Welding joins thermoplastic-coated textiles without thread by fusing layers:

- RF welding(electromagnetic heating, ideal for PVC/TPU)

- Hot-air welding(directed hot air softens coating, then pressure fuses)

- Hot-wedge welding(heated metal wedge inserted between layers)

- Ultrasonic welding(vibration-based localized melting)

Produces:

- A continuous fused seam

- Zero needle holes

- High structural integrity

Technical guidance on welded seams is supported by ISO waterproof testing standards, such as ISO 811 for hydrostatic pressure measurement.

2. Head-to-Head Comparison: Welded vs. Stitched Construction

Seam Technology Comparison Table

| Aspect | Welded Seams | Stitched Seams |

| Joining Method | Melts and fuses coatings | Needle + thread penetration |

| Needle Holes | ❌ None | ✔ Yes — every stitch |

| Waterproofness | Excellent (IPX6–IPX7) | Moderate (IPX3–IPX5 w/ seam tape) |

| Seam Strength | Higher shear/peel | Weakened at perforations |

| Aesthetic | Smooth, modern, minimal | Traditional, visible stitching |

| Machinery Cost | Higher (specialized) | Lower (common sewing machines) |

| Suitable Materials | PVC, TPU, PE films | Almost all textiles |

| Operator Dependency | Low after calibration | High (skill-based) |

Multiple engineering studies show welded seams outperform stitched ones in leak resistance and long-term durability.

TIP: If “fully waterproof” is required (dry bags, submersible duffels), start with welded seams.

3. Advantages of Welding Technology

3.1 Superior Waterproofness

Welded seams eliminate needle holes entirely. Benefits:

- Continuous barrier against water

- Higher hydrostatic pressure resistance

- Better for immersion or heavy rain environments

- Meets IPX6–IPX7 when paired with correct fabric + sealing design

Performance benchmarks align with standardized testing procedures from ASTM.

TIP: For kayak dry bags or marine gear, specify welded seams in the tech pack from day one.

3.2 Higher Seam Strength & Durability

Because no fibers are punctured:

Stronger in peel & shear tests

No thread degradation (UV or abrasion)

Ideal for high-stress areas

Engineering reports have observed that welded TPU/PVC structures maintain integrity longer under repeated load cycles.

TIP: For rescue teams, rafting guides, or expedition operators, welded constructions dramatically reduce failure points.

3.3 Cleaner Aesthetic & Slimmer Profile

Welded seams deliver:

- Zero seam allowance bulk

- Minimalist look

- Easier logo placement

- Better structure for molded panels

Common in premium waterproof accessories and modern technical packs.

TIP: If your brand identity is “performance x modern,” welded panels match the visual language.

3.4 Repeatable, Automated, Consistent

Once welding parameters are set:

- Machines output highly consistent results

- Lower human-error variation

- Supports mass-production scaling

- Reduces rework and scrap

TIP: For orders above 10,000 units, automated welding offers better yield rates vs. hand-stitching.

4. Disadvantages & Limitations of Welding

4.1 Higher Upfront Cost

RF, hot-air, and ultrasonic welders are expensive.

Tooling for complex shapes also adds cost.

TIP: For very low MOQs (under 500 pcs), welding may not be cost-optimal.

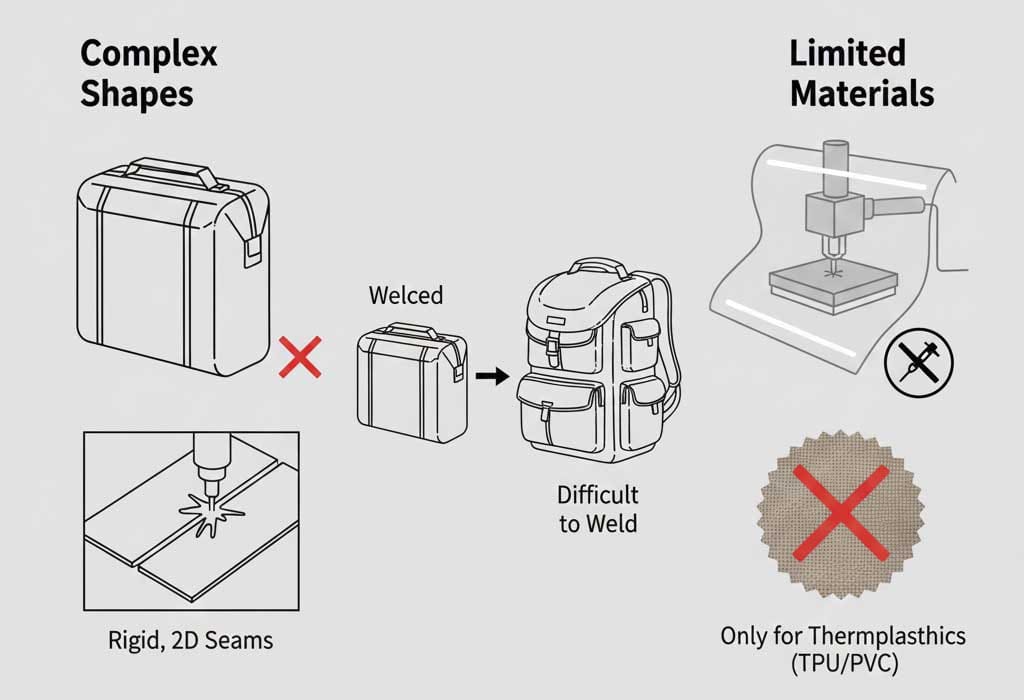

4.2 Material Compatibility Limits

Can weld:

- PVC-coated polyester

- TPU-laminated nylon

- Some PE/PU films

Cannot weld:

- Canvas

- Uncoated nylon/polyester

- High-melting-point fabrics

TIP: Decide the fabric system early—weldability determines design feasibility.

4.3 Limited 3D Complexity

Welding struggles with:

- Tight curves

- Small gussets

- Multi-layer composites

Stitching is often easier for intricate designs.

4.4 Harder to Repair in the Field

A broken stitch can be re-sewn, but:

- A torn weld needs patching

- Large failures require factory repair

5. Advantages of Traditional Stitching

5.1 Works on All Materials & Shapes

Stitching is suitable for:

- Canvas

- Nylon (uncoated)

- Mesh

- Leather

- Foam laminates

- Internal pockets, gussets, organizers

TIP: For highly functional travel packs with many compartments, stitching remains necessary.

5.2 Lower Startup Cost

- Machines are inexpensive

- Operators widely available

- Easy to scale number of sewing lines

Often ideal for new brands testing small volumes.

5.3 Classic Aesthetic

Visible stitching conveys:

- Craft

- Ruggedness

- Heritage outdoor vibes

Preferred for lifestyle or luggage-style products.

5.4 Easy Repairs

A torn panel can be replaced; seams can be re-stitched without special tools.

6. Disadvantages of Stitching in Waterproof Applications

6.1 Needle Holes = Natural Leak Points

Every stitch creates a perforation. Even with seam tape:

- Tape can lift over time

- Heavy bending weakens adhesion

- Hydrostatic pressure forces water through needle holes

Industry comparisons have repeatedly observed that stitched + taped seams rarely match welded seams under immersion-level testing.

TIP: For weather-resistant packs stitching is acceptable; for immersion-level waterproofing, welded seams are the only reliable option.

6.2 Bulkier, Heavier Seams

Stitched seams include:

- Seam allowance

- Thread bulk

- Binding tape

- Excess layers

This adds weight and reduces foldability, especially for dry bags that rely on compact roll-top compression.

6.3 Operator-Dependent Quality

Stitching relies heavily on operator skill:

- Poor tension = seam puckering

- Misalignment = exposed gaps

- Fatigue = inconsistent quality

In large-volume runs, quality variation becomes more noticeable.

TIP: Use clearly defined AQL standards for stitched components and require sealing tape QC checkpoints.

7. When to Use Welding, Stitching, or Hybrid Construction

Most high-performance waterproof bags use a mix of both techniques.

The following matrix helps OEM/ODM buyers decide:

Application & Recommended Seam Strategy Matrix

| Product Type | Recommended Seam Strategy | Reason |

| Classic roll-top dry bags | Fully welded shell | Prevents water ingress under pressure |

| Submersible duffels | Mostly welded + minimal stitching | Shell integrity critical |

| Urban waterproof backpacks | Welded main compartment + stitched harness | Water protection + comfort |

| Travel weather-resistant packs | Stitched + taped | Complex pockets/structure |

| Multifunction outdoor packs | Mostly stitched | Many components |

| Promotional waterproof bags | Stitched | Cost-driven |

Industry references have observed that welding should be prioritized for high-risk waterproof zones.

TIP: Map your “critical waterproof zones” first, then choose welded or stitched seams accordingly.

8. OEM/ODM Perspective: Cost, Capacity, and Factory Selection

China remains the global center of waterproof bag manufacturing, especially for RF-welded dry bags, marine-grade duffels, TPU-coated packs, and technical waterproof backpacks. While Southeast Asia has strong sewing capabilities, the most advanced welding expertise, machinery, and stable mass-production systems are still concentrated in China.

8.1 Strengths of Chinese Waterproof Bag Factories

China’s dominance in waterproof bag welding is driven by several key factors:

Largest Concentration of Welding Facilities

Regions such as Fujian, Guangdong, and Zhejiang host a dense cluster of factories equipped with RF welding, hot-air welding, and ultrasonic welding lines—many with 10–20 years of experience in waterproof bag construction.

Complete Supply Chain for Weldable Materials

China produces nearly all the essential materials for welded waterproof bags, including PVC-coated polyester, TPU-laminated fabrics, rPET TPU, and PFAS-free coatings. Having both materials and manufacturing in one region reduces cost, MOQ, lead time, and risk.

Highly Skilled Technicians

Welding TPU and PVC requires precise control of temperature, pressure, humidity, and cooling time. China has the largest pool of skilled welding technicians capable of maintaining consistency during large-volume production.

Fast Sampling and Tooling Development

China’s industrial ecosystem supports rapid development of welded prototypes, tooling, molds, and jigs, allowing brands to shorten development cycles and accelerate testing.

Stable and Repeatable Mass Production

Welding is sensitive to equipment calibration and environmental conditions. Experienced Chinese factories are able to deliver consistent weld strength and waterproof performance across large orders.

8.2 When Southeast Asia Is Still Suitable

Although core waterproof shell welding is best performed in China, Southeast Asian factories—particularly in Vietnam, Myanmar, and Indonesia—excel in:

- Shoulder straps and harness construction

- Internal pockets and organization panels

- Sewn sub-assemblies

- High-volume sewing at competitive costs

For cost-driven projects, brands may choose a hybrid structure: welded shells produced in China, and sewn components produced in Southeast Asia.

OEM/ODM Tip

When requesting quotations, clearly specify which seams must be welded, which may be stitched, the required waterproof rating (IPX4/IPX6/IPX7), and your preferred material system (PVC/TPU/rPET TPU). This ensures accurate costing and prevents factories from substituting stitched seams in critical waterproof zones.

8.3 Factory Decision Matrix

| Product Type | Recommended Region | Reason |

|---|---|---|

| Fully welded dry bags (PVC/TPU) | China | Most advanced welding capability and material supply |

| Hybrid waterproof backpacks (welded + sewn) | China for welded shell; SEA for sewn parts | Balanced cost and performance |

| Outdoor packs with multiple pockets | Southeast Asia | Strong sewing efficiency and cost advantage |

| Premium marine/rafting waterproof gear | China | Highest waterproof integrity and reliability |

8.4 Key Takeaways for Importers

China remains the most mature and reliable source for waterproof welding technology.

Choose China for any product requiring welded waterproof shells.

Use Southeast Asia for complex sewn components and cost-driven sewing work.

Consider hybrid production—China for welding, Southeast Asia for stitching—when balancing tariff, cost, and capacity.

9. Vancharli Outdoor’s Professional Seam Engineering Solutions

Vancharli Outdoor provides an engineering-based approach to help global brands balance waterproof performance, cost, and manufacturability. With 30+ years of experience and production bases in China, Vietnam, Indonesia, and Myanmar, we support both premium welded bags and complex stitched constructions.

We offer:

- RF / hot-air / hot-wedge / ultrasonic welding

- Hybrid construction engineering

- Material compatibility testing

- CAD seam engineering & tooling development

- Hydrostatic pressure testing, peel-strength verification, AQL inspection

- Multi-country production planning for tariff optimization

If you’d like technical guidance for your next waterproof collection, you may contact our engineering team directly via:

Our Story

10. Practical Checklist Before Finalizing Your Waterproof Bag Tech Pack

Waterproof Requirement

- Splash-proof?

- Heavy rain?

- Submersion?

Target Customer

- Budget outdoor?

- Premium technical?

Material System

- PVC? TPU? rPET TPU?

- Are they weldable?

- Do you need PFAS-free coatings?

Usage Environment

- Marine (saltwater)

- Desert (abrasion)

- Urban commuting

- Professional rescue

Repairability Requirements

- Field repair easy? (stitched)

- Factory repair acceptable? (welded)

MOQ & Projected Volume

- High volume → welding automation is cost-effective

- Low volume → stitched + taped may reduce startup cost

TIP: Ask your manufacturer for two options in your quotation sheet:

“Fully welded shell” vs. “Stitched + taped shell”.

Compare cost deltas and performance requirements before deciding.

11. Conclusion

Welding technology has transformed how modern waterproof bags are made:

- Welded seams provide superior waterproofness, cleaner aesthetics, higher seam strength, and manufacturing consistency.

- Traditional stitching remains essential for complex 3D structures, functional pockets, mixed materials, and repairability.

Most successful outdoor brands use a hybrid method—welded shells where waterproof integrity is critical, stitched sections where structure and features matter.

Final

If you’re planning a waterproof bag collection and want help determining the ideal construction method (welded, stitched, or hybrid), Vancharli Outdoor’s OEM/ODM team can support you from materials to mass production.

FAQ

Q1. Are welded seams always better than stitched seams?

No. Welded seams are better for waterproof performance, but stitched seams offer better flexibility, pocket structure, and complex patterning.

Q2. Can TPU be welded more easily than PVC?

TPU welds more cleanly and has higher long-term durability, but is more expensive. PVC welds easily and is more cost-effective.

Q3. Why do some waterproof backpacks still use stitching?

Because harness systems, pockets, organizers, and zippers all require stitching. Full welding is only possible for simple shells.

Q4. What waterproof rating can welded seams achieve?

High-quality welded seams can reach IPX6–IPX7, depending on the roll-top and zipper design.

Q5. Does welding require special tooling?

Yes. RF welding, ultrasonic welding, and hot-air welding often require custom molds, jigs, or fixtures—especially for 3D shapes.

Q6. Are welded bags harder to repair?

Usually yes. Welds require patching or heat treatment, while stitched seams can be re-sewn easily.

Q7. Does the factory location matter for welding quality?

Yes. Some regions (e.g., Indonesia, Southern China) have more mature welding lines, while Vietnam excels in stitching-heavy technical packs.

See Also

How Global Brands Select Their Waterproof Bag Manufacturer

How Manufacturers Test Waterproof Bags: IPX Standards Explained

What Cooler is As Good as Yeti But Cheaper

The Development Direction of Waterproof Bags in Environmentally Friendly Biodegradable Materials

Why Are 100% Waterproof Bags So Expensive? Cost Breakdown for Buyers

Comments are closed