Why Are 100% Waterproof Bags So Expensive? Cost Breakdown for Buyers

Introduction: The Buyer’s Question

When sourcing managers compare bags, one question always arises: “Why are 100% waterproof bags so expensive compared to normal bags?”

The truth is, cost has less to do with marketing and more with reality: high-performance materials, advanced construction methods, rigorous testing, and certifications.

According to Cognitive Market Research, the waterproof bag market is projected to grow from $5.9 billion in 2021 to $11.7 billion by 2033, fueled by outdoor demand and stricter compliance requirements.

Source: Cognitive Market Research

Waterproof vs. Water-Resistant: The Price Gap

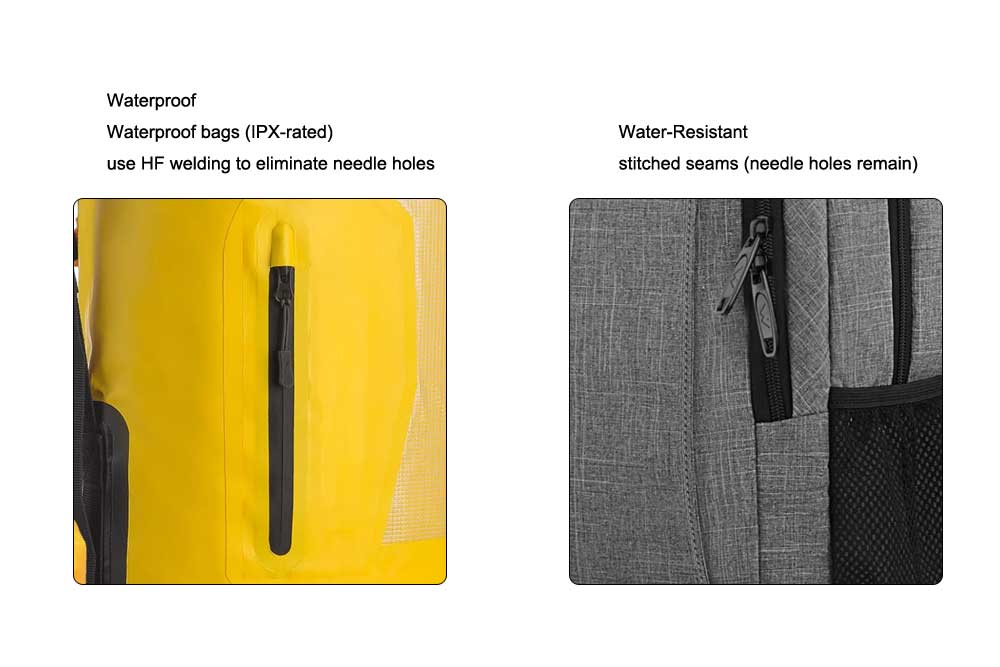

Not all “waterproof” bags are created equal. Many products marketed as “waterproof” are in fact only water-resistant.

– Water-resistant bags are made with stitched seams (needle holes remain) plus PU-coated zippers or flaps. Seam tape can reduce leakage but cannot fully eliminate it. As a result, these bags can survive daily rain but fail when submerged or exposed to heavy water pressure.

– Waterproof bags (IPX-rated) use HF welding to eliminate needle holes, combined with airtight zippers or roll-top closures. These bags are tested to survive immersion without leaking.

That’s why the price gap is significant: A commuter’s water-resistant backpack costs $20–40, while a fully waterproof dry bag costs $50–150 depending on size, materials, and certifications.

In short: Stitching = splash protection. HF welding = immersion protection.

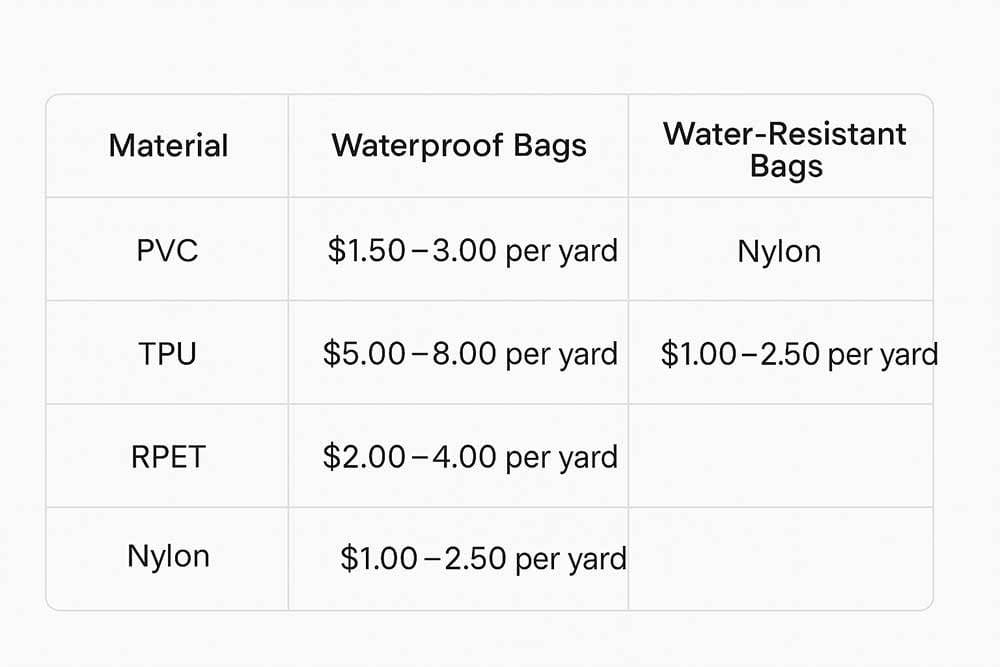

Material Costs: Water-Resistant vs Waterproof Fabrics

Material selection is the first and most critical driver of waterproof bag costs. Different fabrics not only vary in price but also determine whether the bag can be produced using HF welding technology to achieve true waterproof performance.

- Water-Resistant Fabrics (Nylon/Polyester + Coating)

- Cheapest option, used in commuter or lightweight packs.

- Typically PU-coated or DWR-treated to resist light rain and splashes.

- Cannot be HF welded, only stitched—needle holes remain, making IPX certification impossible.

- 30–50% cheaper than PVC/TPU.

- PVC (Polyvinyl Chloride)

- Most common 100% waterproof fabric, thickness ranges 0.3–0.7mm.

- Pros: weldable, durable, abrasion-resistant, cost-effective.

- Cons: heavy, non-eco, increasingly restricted in EU/US markets.

- Best choice for entry-level waterproof bags.

- TPU (Thermoplastic Polyurethane)

- Premium alternative to PVC.

- Pros: lighter, flexible, abrasion-resistant, performs well at low temperatures, eco-friendlier.

- Cons: 20–50% more expensive than PVC.

- Preferred by EU/US buyers due to compliance and superior user experience.

- RPET (Recycled Polyester with TPU/PVC Laminate)

- Made from recycled plastic bottles, laminated with waterproof film.

- Pros: eco-friendly, GRS-certified, strong sustainability marketing value.

- Cons: 30–60% more expensive, supply chain and certification add extra costs.

- Positioned for high-end brands targeting eco-conscious consumers.

- Specialty Materials (Niche Applications)

- Cordura-coated nylon: for military/tactical packs—strong abrasion resistance.

- EVA/TPU films: for ultralight waterproof products.

- Biodegradable bio-based films: emerging, still under development.

| Material | Common Use | Features | Cost vs Baseline | Buyer Implications |

| Nylon/Polyester (coated) | Water-resistant bags | Light, cheap, flexible; DWR/PU coating adds splash resistance but not weldable | Lowest | Only good for commuter packs, not IPX waterproofing |

| PVC | Waterproof bags | Weldable, tough, heavy, poor eco profile | Baseline | Cost-efficient for waterproofing, eco limits |

| TPU | Waterproof bags | Weldable, lighter, flexible, abrasion-resistant, eco-friendlier | +20–50% | Premium durability & compliance |

| RPET (GRS) | Eco waterproof bags | Recycled polyester laminated with TPU/PVC film | +30–60% | Highest cost, eco marketing & compliance |

Reference: Trailven article

Tip for Buyers: TPU and RPET are preferred in EU/US markets due to sustainability compliance. If your target market is eco-sensitive, investing in these materials pays off.

Construction Costs: Why Build Matters

Even with the best materials, construction quality determines whether a bag is truly waterproof or just splash-proof. In fact, construction is often the largest cost driver.

- Stitching (Water-Resistant Bags)

- Process: Needle and thread penetrate fabric, leaving holes.

- Cost Advantage: Cheap machines, quick worker training.

- Drawback: Needle holes remain. Seam tape reduces leakage but cannot eliminate it.

- Market Positioning: Suitable for daily commuter or fashion packs, but not immersion or pressure environments.

- High-Frequency Welding (HF Welding, 100% Waterproof Bags)

- Process: Uses high-frequency waves to fuse PVC/TPU molecules into seamless bonds.

- Equipment Cost: Each machine costs $30,000–50,000, with high electricity consumption.

- Technical Skill: Requires trained operators to control temperature, voltage, and pressure.

- Yield Rate: Small errors cause seam failures, increasing scrap and waste.

- Cost Impact: At least 50% more expensive than stitching, but essential for true waterproofing.

- Labor & Efficiency Gap

- HF welding operators need months of training and earn higher wages.

- Installing airtight zippers and testing every weld seam takes significantly more time.

- A stitched line may produce 10,000 pcs/month, while HF welding typically outputs 3,000–5,000 pcs/month.

- Lower throughput directly raises unit cost.

- Machine Maintenance & Energy Consumption

- HF welding machines require electrode replacement and regular calibration.

- High energy usage adds to factory overhead costs.

- These indirect costs are factored into the final quotation.

Waterproof vs Water-Resistant Construction

| Aspect | Water-Resistant | True Waterproof | Cost Impact | Notes |

|---|---|---|---|---|

| Base Fabric | Coated nylon/poly | PVC/TPU laminates | +20–40% | HF welding requires weldable films |

| Seams | Stitched + seam tape | HF welding (no needle holes) | +30–50% | Only HF welding guarantees watertight |

| Closure | PU zipper, flaps | Roll-top/airtight resin zipper | +3–10 USD | Mandatory for immersion |

| Testing | Rain/splash | IPX5/7/8 immersion | +5–15% | Lab certification adds cost |

| Durability | Light rain only | Immersion & hydrostatic pressure | Priceless | Prevents recalls |

| Labor Efficiency | High (fast, low skill) | Low (skilled, slower, tested) | +20–30% | Often underestimated |

| Machine Maintenance | Minimal | Requires calibration & electrodes | +10–15% | Overhead added per unit |

Tip:HF welding ensures immersion waterproofing, but also raises costs. Ask your supplier if their operators are certified and experienced.

Zippers & Closures

Closures are often underestimated, but they can make or break a waterproof bag. Even with the best fabrics and welding, a weak closure means water leakage.

- PU-Coated Zippers (Water-Resistant)

- Mechanism: A PU coating sprayed over standard coil zippers to repel water.

- Waterproof Level: Effective against light rain and splashes, but fails under heavy rain or immersion.

- Cost Impact: Very low (adds about $0.5–1 per zipper).

- Market Use: Ideal for commuter packs, not suitable for outdoor immersion gear.

- Resin Airtight Zippers (True Waterproof)

- Mechanism: Toothless, air-sealed structure, similar to wetsuit zippers.

- Waterproof Level: Withstands immersion, often required for IPX7–IPX8 products.

- Cost Impact: Adds $3–10 per zipper, installation requires skill.

- Market Use: Essential for dry bags, diving gear, tactical/military waterproof packs.

- Roll-Top Closures

- Mechanism: Fabric top rolled multiple times and secured with buckles.

- Waterproof Level: Excellent for immersion, especially in large-volume bags.

- Cost Impact: Moderate, but requires reinforced fabric and buckle systems.

- Market Use: River rafting, kayaking, camping, large-capacity bags.

- Magnetic/Innovative Closures (Emerging Trend)

- Mechanism: Uses magnetic strips combined with welded edges.

- Advantages: Convenient, sleek design, trending in fashion-outdoor hybrids.

- Drawbacks: High cost, limited large-scale adoption, niche applications.

| Component | Description | Waterproof Level | Cost Impact | Best Use |

|---|---|---|---|---|

| PU-coated zipper | Coil zipper with PU spray | Rain/splash | Low | Commuter packs |

| Resin airtight zipper | Air-sealed, toothless system | Immersion-ready | +3–10 USD | Dry bags, diving gear, tactical packs |

| Roll-top closure | Multi-fold roll + buckle | Immersion-ready | Medium | River/camping bags |

| Magnetic closure (emerging) | Magnets + welded seams | Splash/partial waterproof | High | Premium fashion/outdoor bags |

Tip:Closures are the real waterproof test. If a supplier offers “cheap waterproof bags,” check the closure first. True waterproofing requires airtight zippers or roll-top designs.

Testing & Certification: The Hidden Price Tag

To market “100% waterproof,” suppliers must pay for third-party testing.

– IPX (IEC 60529): IPX5 = splash, IPX7 = 1m submersion, IPX8 = deeper submersion.

– Compliance: REACH and RoHS.

Testing adds 5–15% to cost but prevents rejections and recalls.

Reference: IEC IP Ratings

Case Studies: When Cheap Becomes Expensive

1. The Recall Cost: A U.S. brand chose stitched construction to save 20%. Bags leaked, 1,200 units were returned, costing $50,000.

2. The Certified Advantage: A European importer paid 20% more for HF-welded, IPX-tested bags. Passed audits on the first try and launched 3 months earlier.

Vancharli Advantage: Balancing Cost and Value

Vancharli (founded 1995, 30 years’ expertise) provides:

– Materials: PVC, TPU, RPET

– Process: HF welding, airtight zippers

– Global Footprint: 5 bases (China HQ, Xiamen, Myanmar, Vietnam, Indonesia)

– Certifications: ISO, BSCI, SEDEX, GRS, IPX

– Buyer Benefits: Lower audit costs, faster approvals, eco-marketing value.

Learn more: Our Story | Custom Fabrics | Free Sample Design

Buyer’s Checklist

| Question | Why It Matters | What to Verify |

| PVC vs TPU? | Defines cost & weldability | Ask for HF-weldable films |

| HF welding or stitching? | Key to waterproofing | Require HF-welded seams |

| Airtight zipper or roll-top? | Immersion performance | Specify resin airtight zipper |

| IPX reports? | Compliance | Ask for IPX5/7/8 tests |

| REACH/RoHS? | Market entry | Request compliance docs |

See also

Complete Guide to Choosing the Right Capacity Waterproof Bag

How to make waterproof bags: the latest guide for 2025

What You Need to Know About Waterproof Tape for Bags in 2025

Certifications to Look for When Choosing a Waterproof Bag Manufacturer

Comments are closed