How to make waterproof bags: the latest guide for 2025

To understand the waterproof bag design process, you start by selecting strong waterproof fabrics. It’s essential to seal every seam effectively. Utilizing closures that prevent water from entering is crucial. Choosing the right materials ensures excellent waterproof protection. In 2025, new trends are emerging in the waterproof bag design process, including eco-friendly fabrics, smart closures, and improved sealing methods. As outdoor activities continue to grow, more people are seeking waterproof storage solutions.

The global waterproof bag market is projected to reach $11,725.3 million by 2033. With an increasing number of individuals wanting to protect their electronics and gear from water, learning how to design a waterproof bag becomes invaluable. You can create a waterproof bag that is durable and long-lasting.

Key Takeaways

- Pick strong waterproof fabrics like TPU or PVC. These fabrics last long and keep water out. Seal every seam well with heat tape or welded seams. This stops water from leaking in. Use roll-top closures for a tight seal. This keeps water from getting inside your bag. Choose the right tools, like a heavy-duty sewing machine. Use a non-stick presser foot to make sewing easier. Test your waterproof bag with immersion and spray tests. This helps you know if your bag is really waterproof. Take care of your waterproof bag by cleaning it often. Check for damage to help your bag last longer. Try eco-friendly materials and smart features in new bag designs for 2025. Follow each step, from planning to putting it together, to make a good waterproof bag.

Materials for Waterproof Bags

Waterproof Fabrics

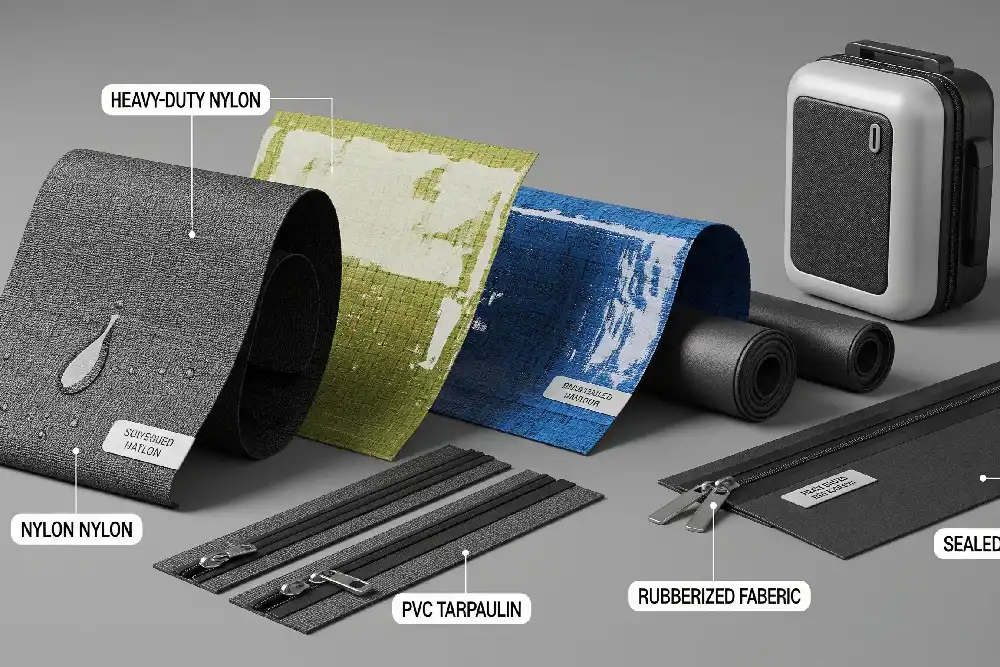

Picking the right materials is the first thing you do. You need fabrics that stop water and keep your stuff safe. In 2025, there are new choices for waterproof backpacks and waterproof duffel bags. You can also find ways to waterproof canvas bags.

PVC, TPU, and Vinyl

PVC, TPU, and vinyl are common for waterproof bags. These have a plastic-like surface that blocks water. You see them in many waterproof duffel bags and waterproof backpacks. TPU is lighter and better for the environment than PVC. Vinyl is strong and good for waterproofing canvas bags. These materials do not tear easily and last a long time.

Polyester with Coatings

Polyester can be waterproof if you add coatings. Polyurethane-coated polyester is used in waterproof backpacks and waterproof duffel bags. The coating makes the fabric tough and keeps water out. Polyester with DWR finishes helps water slide off. Many people use polyester for waterproofing canvas bags because it bends easily and is simple to sew.

Tip: For heavy rain, try advanced fabrics like 420D Spectron or X-Pac RX30. These give great protection in wet places.

Here are some top waterproof fabrics in 2025:

- 420D Spectron: Best for heavy rain and wet places

- X-Pac RX30: Great for strong rain storms

- 630D & 1050D HT Ballistic Nylon: Good for steady rain

- 200D Halcyon & 210D Cerylon: Best for light rain or inside linings

| Fabric Type | Water Protection Level | Best For |

|---|---|---|

| Water-resistant | Moderate | Light to moderate rain |

| Water-repellent | High | Blocking tiny holes |

| Waterproof | Excellent | Big rain, underwater use |

| 420D Spectron | Excellent | Heavy rain, all-weather use |

| X-Pac RX30 | Excellent | Strong rain storms |

| 630D & 1050D HT Ballistic Nylon | High | Steady rain, daily use |

| 200D Halcyon & 210D Cerylon | Moderate | Light rain, little moisture |

Closures and Hardware

The closure you pick matters as much as the fabric. You want to keep water out of your waterproof bag. So, you need closures that are strong.

Roll-Top Closures

Roll-top closures are the best for waterproof bags. You fold the top three times and clip it shut. This makes a tight seal that stops water. Many waterproof duffel bags and waterproof backpacks use this style.

Waterproof Zippers

Waterproof zippers have special designs to block water. Some have overlapping parts or teeth that lock together. TRU Zip and YKK Aquaguard are two well-known types. These zippers work for waterproofing canvas bags and other things. HydroLok zippers are a top choice with no way for water to get in.

Sealing Supplies

You need the right supplies to seal seams and make your waterproof bag last.

Urethane Heat Tape

Urethane heat tape covers seams and keeps water out. You use heat to stick the tape to the fabric. This works well for waterproofing canvas bags and other materials.

Welded Seams

Welded seams use heat or radio waves to join fabric. This makes a strong, waterproof seal. Many waterproof backpacks and waterproof duffel bags use welded seams for extra strength.

Note: New sealing methods in 2025 use two or three layers for even better waterproof protection.

Tools for DIY

You need the right tools to make a strong waterproof bag. The right tools help you work faster and make your waterproof bag last longer. In 2025, you can find many new tools that make the process easier. You do not need to buy expensive machines. Most tools are easy to find at craft stores or online.

Here is a list of tools you should have for making a waterproof bag:

- Heavy-duty sewing machine: You need a sewing machine that can handle thick waterproof fabrics. Many home machines work if you use the right needle.

- Non-stick or Teflon presser foot: This tool helps you sew sticky materials like PVC or TPU. The fabric will not stick to the foot, so you get smooth seams.

- Sharp scissors or rotary cutter: You must cut waterproof fabrics cleanly. Sharp scissors or a rotary cutter make straight lines and prevent fraying.

- Heat gun or seam sealing iron: You use these tools to apply urethane heat tape or weld seams. A heat gun gives you control over the temperature. A seam sealing iron works well for straight seams.

- Measuring tape and ruler: You need to measure your fabric and seams. Accurate measurements help your waterproof bag fit together perfectly.

- Clips or binder clips: Pins can leave holes in waterproof fabric. Use clips to hold pieces together before sewing.

- Seam roller: This tool presses down heat tape or welded seams. You get a tight seal that keeps water out.

- Marking tools: Use chalk or washable markers to mark your fabric. These marks help you cut and sew in the right places.

Tip: Always test your tools on a scrap piece of waterproof fabric before you start your project. This helps you avoid mistakes on your main waterproof bag.

| Tool | Purpose | Why It Matters for Waterproof Bags |

|---|---|---|

| Heavy-duty sewing machine | Sewing thick waterproof fabrics | Strong seams keep water out |

| Non-stick presser foot | Sewing sticky materials | Prevents fabric from sticking |

| Heat gun/seam sealing iron | Applying heat tape or welding seams | Creates a waterproof seal |

| Seam roller | Pressing seams and tape | Ensures no water leaks through seams |

| Clips | Holding fabric without holes | Keeps waterproof layer intact |

You can also use a hole punch for grommets or eyelets if you want to add straps or drainage holes. Always keep your tools clean. Dirt or glue can damage waterproof fabrics and affect the waterproof seal.

When you use the right tools, you make a waterproof bag that stands up to rain, splashes, and even full submersion. You get a professional finish and a waterproof bag you can trust for any adventure.

Waterproof Bag Design Process

Planning & Measuring

First, you need to plan your waterproof bag project. Think about what you want your waterproof bag to do. Pick a size that works for you. Decide if you want a backpack, duffel, or pouch. Think about how you want it to look. Add features that make it stronger, like extra layers or tough corners.

When picking materials, look at PVC if you want something strong and cheap. TPU is tough and better for the planet. Polyester and nylon keep water out and work for most bags. RPET is good for the earth but can cost more.

| Material | Properties | Considerations |

|---|---|---|

| PU | Lightweight, flexible | Good for general use |

| PVC | Durable, affordable | Commonly used for waterproofing |

| TPU | Eco-friendly, strong | Ideal for environmentally conscious designs |

Decide which parts of your waterproof bag will block water. Use waterproof fabric inside for lining. Pick special fabric for the outside to stop rain and dirt. Make sure your design lets you use hot pressed waterproofing. This makes your waterproof bag even better.

Tip: Measure everything two times before you cut. This helps you not waste fabric and makes sure your waterproof bag fits right.

Here are the main steps for planning and measuring: Choose the size you want. Think about the style. Add features that make it last longer. Make sure your waterproofing works well.

Cutting Materials

Next, cut your materials for your waterproof bag. Use sharp scissors or a rotary cutter for neat edges. Pattern weights hold your fabric in place. Do not use pins because they make holes and let water in.

With waterproof fabrics like PU or PVC, you do not need to worry about the grainline. This means you can put your patterns anywhere. Try not to make too many holes when cutting. Each hole can make your waterproof bag weaker.

- Use pattern weights, not pins.

- Cut slowly and keep your edges smooth.

- Check your measurements again before you cut.

Note: Clean cuts help your seams seal better and make your waterproof bag last longer.

Seam Sealing

Seam sealing is very important for your waterproof bag. Water can get in through seams, so you must seal them well. There are different ways to seal seams. Each one helps your waterproof bag last longer and keeps water out.

| Method | Description |

|---|---|

| Seam Grip WP | Seals seams from the outside, great for hard-to-reach areas. Apply inside and outside for double protection. |

| Iron-on Seam Tape | Strong bond, works well on curves. Quick and effective for repairs. |

| Gluing | Use contact cement for cloth-backed tape. Clean surfaces for best results. |

Seam sealing gives you: Stronger waterproof bags. Better waterproofing to keep things dry. More protection from wind and dirt. You save money because your waterproof bag lasts longer.

“Tests show that melted fusible threads make seams more waterproof. This means needle holes in fabric can be covered by melted fusible sewing thread.”

Heat Tape Application

Heat tape covers seams and stops water from getting in. Put the tape over the seam. Use a heat gun or iron to make it stick. Move slowly so the tape sticks well. Press with a seam roller for a tight seal. Heat tape works best on straight seams and is fast to use.

Steps for heat tape application:

- Put the tape on the seam.

- Use a heat gun or iron to make it sticky.

- Press with a seam roller for a strong seal.

This covers needle holes and adds more protection. Many people use this method in waterproofing tutorials.

Welding Techniques

Welding is a new way to make waterproof bags. It uses heat or sound waves to join fabric. You do not use needles, so there are no holes for water. Welding makes a strong, waterproof seam. Many tutorials say this is the best way to protect your waterproof bag.

- Use ultrasonic welding for a strong, smooth finish.

- Heat sealing melts fabric layers together.

- Welded seams are used in fancy waterproof bags.

Welding gives you: No needle holes, so water stays out. Strong seams that last a long time. A smooth look that seems professional.

Pro Tip: Always test your seam sealing on a scrap piece first. This helps you not make mistakes and gives the best protection.

The waterproof bag design process needs good planning, careful cutting, and strong seam sealing. These steps help you make a waterproof bag that keeps out rain and splashes. Follow each tutorial step to get the best results and keep your gear safe for a long time.

Attaching Closures

You need to attach closures carefully to keep your bag waterproof. The closure is the last barrier that stops water from getting inside. If you do this step well, you improve the waterproof quality of your bag.

Step-by-Step: Roll-Top Closure

Many waterproof bags use a roll-top closure. This method gives a strong seal and is easy to use. Follow these steps to attach and use a roll-top closure:

- Prepare your bag. Do not overfill it. Leave enough space at the top so you can roll it down.

- Align the top edges. Hold the bag upright and make sure the edges are smooth and free from dirt.

- Roll the top tightly at least three times. Rolling creates a barrier that blocks water.

- Secure the closure. Buckle the ends together. Pull the rolled fabric tight to keep the seal strong.

- Test the seal. Press on the bag. If you hear air escape, unroll and try again.

Tip: Folding the top instead of rolling can also work. Fold it down firmly three times for a sharp, water-blocking edge.

Best Practices for Closures

- Keep the closure area clean. Dirt can break the waterproof seal.

- Pick the right size bag for your gear. A good fit helps the closure work better.

- Try dual closure systems for extra protection. Some waterproof bags use both a zipper and a roll-top.

- Avoid deep water submersion. Even the best closure may let water in if you go too deep.

- Practice using the closure. The more you use it, the better your waterproof quality will be.

Closure Types and Waterproof Performance

Different closure methods affect how waterproof your bag will be. Here is a table that shows how some common attachment methods impact waterproof quality:

| Closure Attachment Method | Impact on Waterproof Performance |

|---|---|

| Clip and Rail | Depends on design and how well you install it |

| Aluminum T-Clips | Can improve air and water tightness |

| Long Screws | May affect thermal and waterproof performance |

You want to choose a closure that matches your needs. Roll-top closures and waterproof zippers are the most popular for waterproof bags in 2025. They give you a strong seal and are easy to use.

Assembly & Finishing

Now you need to put your waterproof bag together and finish the details. This step makes sure your bag is strong and keeps water out.

Final Assembly Steps

- Fold the raw edges together. Keep the zipper open if your bag has one.

- Sew along the open sides. Use a tight zig-zag stitch for extra strength.

- Turn the bag right side out through the zipper opening.

- Backstitch at the top and bottom of each seam. This keeps the seams from coming apart.

- Finish the edges with a serger or pinking shears. This stops the fabric from fraying.

Note: Always tape the seams on the inside with single-sided Dyneema tape or use heat-activated seam tape. This step boosts the waterproof quality and makes your bag last longer.

Extra Waterproofing Steps

- Apply heat-activated seam tape over all internal stitches. Use a roller heat press to bond the tape.

- Use a liquid seam sealant for small gaps. Brush or inject the sealant, then let it cure for 12–24 hours before using the bag.

You can also cut loops from binding tape and sew them into the sides for handles. Flip the bag inside out after sewing for a clean look. Add a zipper pull with bright thread to make it easy to open.

Quality Control for Waterproof Bags

You want your waterproof bag to work well and last a long time. Quality control checks help you find problems before you use the bag. Here are some common quality control steps:

| Quality Control Measure | Details |

|---|---|

| Final AQL Sampling | Check for major and minor defects in a sample batch |

| Performance Testing | Test for strength, abrasion, water resistance, and hardware pull |

| Key Tests | Use standards like ASTM D5034 for strength and ISO 811 for water resistance |

| Digital Dashboards | Track defect rates and spot trends |

| Third-party Audits | Use BSCI or ISO 9001 to check compliance |

| Corrective-action Reports | Keep major defects below 2% per batch |

Tip: Always test your finished waterproof bag by filling it with air and pressing gently. If air escapes, check the seams and closures again.

When you follow these steps, you create a waterproof bag that stands up to rain, splashes, and even short submersion. Good assembly and finishing give you a bag with high waterproof quality and long-lasting performance.

Waterproof Testing

You need to test your waterproof bag before you trust it in the rain or on your next adventure. Good testing helps you find weak spots and fix them. In 2025, you can use several methods to check if your bag is truly waterproof. These tests help you meet industry standards and keep your gear dry.

Immersion Test

The immersion test checks if your bag can handle being underwater. You fill your bag with dry paper or a towel. Then, you close it tightly and submerge it in a tub or sink. Watch for air bubbles. If you see bubbles, water can get in through the seams or closure. This means you need to improve your waterproof sealing.

Many brands use this test as part of their quality control process. You can also look for bags that meet IPX7 or IPX8 standards. These ratings show how well a bag can resist water during submersion. Here is a table that shows the recommended IPX ratings and fabric strength for different activities:

| Activity | Recommended IPX | Fabric Hydrostatic Pressure |

|---|---|---|

| Commuting | IPX4–5 | ≥5,000 mmH₂O |

| Hiking | IPX5–6 | ≥8,000 mmH₂O |

| Kayaking/Rafting | IPX7 | ≥10,000 mmH₂O |

| Diving/Photography | IPX8 | ≥15,000 mmH₂O |

| Military/Industrial | IPX9K | Custom standards |

Tip: Always check for leaks after the immersion test. Dry the bag and look for wet spots inside.

Spray Test

The spray test helps you see how your bag handles rain or splashes. You place your waterproof bag under a shower or use a spray bottle. Spray water evenly over all sides. After a few minutes, open the bag and check if the inside is dry. This test works well for daily use bags, like those for commuting or hiking.

Some companies use the ISO 811 standard for this test. This standard measures how much water pressure the fabric can handle before leaking. You can compare your results to the table above to see if your bag meets the right level for your activity.

Note: If you see water inside, check the seams and closures. You may need to reseal or reinforce these areas.

Pressure Test

The pressure test checks the strength of your seams and closures. You fill your bag with air, seal it, and gently squeeze. Listen for escaping air or watch for bubbles if you submerge the bag. This method is part of air and water leakage testing. It helps you find small holes or weak spots that other tests might miss.

Here is a table of common waterproof testing methods:

| Method | Description |

|---|---|

| Air Pressure Testing | Inflate the sealed bag and observe for air pressure loss over 24 hours to check for seam integrity. |

| Water Leakage Testing | Submerge the bag in water; air bubbles indicate leaks at seams or closures. |

You can also use third-party labs for testing for water tightness. These labs use special machines and follow strict rules. They check for things like UV aging, salt spray, flex and abrasion, and thermal cycling. These tests make sure your waterproof bag stays strong in many conditions.

Tip: Always include pressure testing in your quality control checklist. This step helps you catch problems before you use your bag outdoors.

When you use these waterproof testing methods, you make sure your bag keeps your gear dry. You also meet the latest standards for 2025. Reliable testing gives you peace of mind and helps your waterproof bag last longer.

Maintenance & Repair

Cleaning Waterproof Bags

Keeping your waterproof bag clean helps it last longer and keeps your gear safe. You should follow these steps for the best results:

- Gather your supplies. You need mild soap, a soft sponge, warm water, a towel, and maybe baking soda or vinegar.

- Empty your waterproof bag and check for dirt or stains.

- Rinse the bag with warm water to remove loose debris.

- Mix warm water with mild soap to make a cleaning solution.

- Use a soft sponge to scrub the bag gently.

- Rinse the bag well to remove all soap.

- Air-dry your waterproof bag in a well-ventilated area. Keep it out of direct sunlight.

- For tough odors, try a baking soda paste or a vinegar solution.

- If you spill food, rinse your waterproof bag right away and use mild detergent.

- Use antibacterial wipes or alcohol sprays for quick cleanups. Wipe down with a wet towel after disinfecting.

- Avoid harsh chemicals like bleach. These can damage the waterproof coating.

- Spray down your waterproof bag and let it air dry after each trip.

Tip: Always inspect your waterproof bag for damage during cleaning. Regular checks help you spot problems early.

Repairing Seams

Even the best waterproof bags can develop leaks at the seams. You can fix most problems at home with the right tools and methods.

Patch Kits

Patch kits work well for small holes or tears in your waterproof bag. Follow these steps:

- Check the damage and make sure the area is dry.

- Clean the spot with isopropyl alcohol.

- Cut a patch at least one inch bigger than the hole.

- Apply a thin layer of adhesive to both the patch and the bag.

- Press the patch in place and use a weight or clamp while it cures.

- After curing, fill your waterproof bag with water to test for leaks.

Resealing Methods

If a seam starts to leak, you can reseal it:

- Clean the seam and let it dry.

- Spread a thin, even layer of adhesive on both sides.

- Align the seam edges and press them together.

- Let the adhesive cure for the time listed on the package.

- For extra strength, add a self-adhesive waterproof patch.

A poly-core thread gives better durability than cotton thread. Using cotton interfacing can help repairs last longer. Many waterproof bags pass seam slippage, tensile strength, and fatigue tests when you use these repair methods.

| Test Type | What It Checks For |

|---|---|

| Seam Slippage Testing | Seams stay tight under stress |

| Tensile Strength Testing | Seams do not break when pulled |

| Fatigue Testing | Seams hold up after many bends and uses |

Note: Cotton-wrapped poly thread combines softness and strength for waterproof bag repairs.

Storage Tips

Proper storage keeps your waterproof bag in top shape:

- Store your waterproof bag in a cool, dry place.

- Keep it out of direct sunlight to protect the waterproof coating.

- Make sure your waterproof bag is completely dry before storing.

- Do not fold or crush your waterproof bag for long periods.

- Hang your waterproof bag or lay it flat to keep its shape.

Remember: Good storage habits help your waterproof bag stay waterproof for years.

Wet Bag Uses & Trends 2025

Everyday Uses

You use a wet bag every day to keep your things safe from water. Many people carry a wet bag when they travel. You protect your phone, wallet, and documents from rain or spills. A wet bag helps you organize your gear for school, work, or sports. You can pack your lunch or gym clothes in a wet bag to keep them dry. During your daily commute, a wet bag keeps your electronics safe, even in heavy rain. You use dry bags for hiking, camping, and fishing trips. Dry bags protect your gear from snow and mud. You can trust a waterproof wet bag to keep your books and papers dry on rainy days. Many students use dry bags for school supplies. You see waterproof backpacks with wet bag liners for extra protection. You use dry bags for swimming or beach trips to keep towels and clothes dry. A wet bag works well for storing wet swimsuits after swimming. You use dry bags for biking or running in wet weather. A waterproof wet bag helps you keep snacks and water bottles dry during outdoor activities.

Tip: Always pack your valuables in a waterproof wet bag before you leave home. You avoid damage from rain or spills.

Eco-Friendly Innovations

You see new eco-friendly wet bag designs in 2025. Many brands use recycled materials for waterproof wet bag fabrics. You choose wet bag options made from RPET or recycled nylon. These waterproof wet bag choices help you protect the planet. You find dry bags with biodegradable coatings. Some wet bag makers use plant-based waterproof treatments. You pick a wet bag with less plastic and more natural fibers. Many waterproof wet bag brands offer reusable packaging. You use dry bags that last longer and reduce waste. You see waterproof wet bag companies support clean water projects. You choose a wet bag with a repair kit to fix small tears. You help the environment by using dry bags instead of single-use plastic bags. You find waterproof wet bag styles with eco-friendly dyes. You pick a wet bag with a lifetime warranty to reduce landfill waste.

| Eco-Friendly Feature | How It Helps You |

|---|---|

| Recycled waterproof fabric | Reduces plastic waste |

| Biodegradable coatings | Breaks down naturally |

| Plant-based waterproofing | Uses fewer chemicals |

| Repairable wet bag designs | Extends product life |

| Reusable packaging | Cuts down on trash |

Smart Features

You discover smart features in waterproof wet bag designs for 2025. Many wet bag brands add USB charging ports. You charge your phone or tablet while you travel. You use dry bags with RFID-blocking pockets to keep your cards safe. Some waterproof wet bag models have GPS tracking. You find your wet bag if you lose it. You use dry bags with built-in power management systems. You keep your devices charged and ready. Many waterproof wet bag styles have touch-screen pockets. You use your phone without opening the wet bag. You see dry bags with Bluetooth speakers for music on the go. You pick a wet bag with a solar panel to charge your gear outdoors. You use waterproof wet bag designs with smart locks for extra security. You find dry bags with LED lights for night hikes. You choose a wet bag with a temperature sensor to protect your food.

Note: Smart waterproof wet bag features help you stay connected, safe, and organized during every adventure.

Troubleshooting Waterproof Bags

Common Issues

You may face problems with your waterproof bag, even if you follow every step. Knowing the most common issues helps you fix them quickly. Here is a table that shows what can go wrong and how you can solve it:

| Issue | Description | Solution |

|---|---|---|

| Choosing the Wrong Size Bag | A bag that is too large or too small can cause sealing problems. | Select the right size for your needs. |

| Overheating the Bag | Too much heat can damage the waterproof material. | Use the correct heat setting and time. |

| Overstuffing the Bag | Filling the bag too much can lead to leaks and weak seals. | Leave enough space at the top for sealing. |

| Incomplete Seals | Gaps in the seal let air and water inside the waterproof bag. | Check that all edges are sealed with no gaps. |

| Improper Use of Oxygen Absorbers | Using the wrong amount can reduce storage effectiveness. | Use the right quantity for your bag and items. |

You might also see leaks if you do not seal the seams well. Sometimes, the waterproof coating can wear off after heavy use. If you notice your waterproof bag feels sticky or thin, check for damage right away.

Tip: Always inspect your waterproof bag before each trip. Early checks help you avoid bigger problems later.

Pro Tips

You can fix small holes or leaks in your waterproof bag at home. Follow these steps to repair your bag and keep it working:

- Inspect your waterproof bag for any damage or holes.

- Clean the damaged area with isopropyl alcohol. This removes dirt and helps the patch stick.

- Cut a patch that is bigger than the hole. Make sure it covers the area well.

- Apply adhesive to both the patch and the damaged spot on your waterproof bag.

- Press the patch in place. Use a weight or clamp to hold it while it dries.

- After the patch dries, test your waterproof bag by filling it with water. Check for leaks.

You can also prevent problems by following these pro tips:

- Do not overfill your waterproof bag. This keeps the seals strong.

- Store your waterproof bag in a cool, dry place. Heat and sunlight can damage the waterproof coating.

- Clean your waterproof bag after each use. Dirt and salt can wear down the waterproof layer.

- Practice sealing and unsealing your waterproof bag. This helps you get a tight seal every time.

- Use only recommended cleaners and adhesives. Some products can harm the waterproof material.

Remember: A little care goes a long way. Regular checks and quick repairs help your waterproof bag last for years.

You now know the essential steps for making a waterproof bag. Choose strong materials, seal seams well, and use smart closures. Try building your own bag with the latest 2025 methods. Share your results or test new designs with friends.

Anyone can create a professional waterproof bag with the right tools and guidance. Start your project today and see what you can achieve!

FAQ

What is the best fabric for a waterproof bag?

You get the best results with TPU or coated polyester. These fabrics block water and last a long time. TPU is lighter and better for the environment. Polyester with a waterproof coating also works well for most projects.

How do you seal seams to keep water out?

You use heat tape or seam sealant. Place the tape over the seam and press with a heat gun or iron. This method covers needle holes and keeps water from leaking inside your bag.

Can you wash a waterproof bag in a washing machine?

You should not use a washing machine. Hand wash your waterproof bag with mild soap and water. Rinse well and let it air dry. Machine washing can damage the waterproof coating.

How do you fix a small hole in a waterproof bag?

You clean the area, then use a patch kit. Cut a patch larger than the hole, add adhesive, and press it on. Let it dry before using your bag again.

What is a roll-top closure and why use it?

A roll-top closure lets you fold the top of your bag three times and clip it shut. This creates a tight seal that keeps water out. Many waterproof bags use this design for extra protection.

How do you test if your bag is waterproof?

You fill the bag with dry paper, seal it, and submerge it in water. Check for bubbles or wet spots inside. If you see any, reseal the seams or closure.

Are eco-friendly waterproof bags as strong as regular ones?

Yes, many eco-friendly bags use recycled nylon or TPU. These materials give you the same strength and waterproof protection as traditional options. Always check the product label for details.

Can you add smart features to a DIY waterproof bag?

You can add features like RFID-blocking pockets or USB ports. Buy ready-made inserts or kits. Follow the instructions to attach them to your bag for extra convenience.

See also

Complete Guide to Choosing the Right Capacity Waterproof Bag

Comments are closed