Waterproof Disc Golf Bags: Keep Your Gear Dry in Any Weather

When it comes to disc golf, performance depends on consistency — not just in your throws, but in the reliability of your equipment.

Imagine a tournament morning: clouds gather, wind picks up, and by the third hole, rain is streaming down your shoulders. Your discs are slick, your towel soaked, and your bag—once your steady companion—is now waterlogged and heavy.

That scene is more than an inconvenience. It’s a design problem.

For professional players, brand designers, and retailers alike, waterproof disc golf bags are not just an accessory—they’re a critical component of reliable performance.

And for brands that produce them, understanding how true waterproofing works is the foundation of both product innovation and customer trust.

Understanding Waterproof vs. Water-Resistant

When consumers search for “waterproof disc golf bags,” they rarely realize that many products on the market are only water-resistant.

The distinction seems subtle but can mean the difference between a confident putt and a soggy round.

| Type | Protection Level | Typical Material | Real Use Example |

| Water-resistant | Handles light rain; repels small splashes | 600D polyester with DWR coating | Suitable for drizzle |

| Water-repellent | Resists moisture temporarily | PU-coated nylon | Moderate showers |

| Waterproof | Fully sealed, no water ingress | TPU-laminated tarpaulin, welded seams | Heavy rain, puddles, mud |

Waterproofing is a combination of material + construction.

A typical stitched polyester bag with a DWR coating may repel droplets but will eventually absorb moisture through seams.

True waterproof disc golf bags rely on laminated fabrics and high-frequency welded seams that fuse material layers without needle holes—creating a seamless shield against the elements, as explained in this comparison.

TIP: If a supplier claims “waterproof,” always check whether seams are welded, not sewn. Stitching is where leaks start.

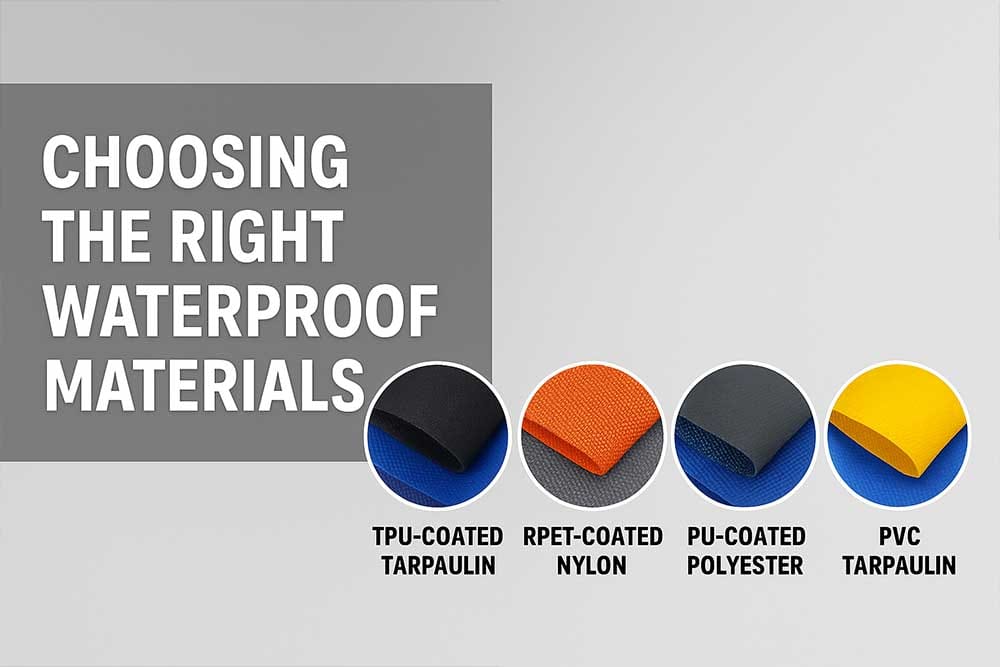

Choosing the Right Waterproof Materials

Materials define performance, weight, and sustainability.

For OEM and ODM brands, selecting the right waterproof fabric isn’t only a design decision—it’s a business one.

1. TPU-Laminated Tarpaulin

A modern evolution of PVC, TPU (thermoplastic polyurethane) is fully waterproof, stretch-resistant, and far more eco-friendly.

It provides outstanding hydrostatic resistance and remains flexible under both hot and cold conditions, making it ideal for premium product lines.

2. rPET TPU-Laminated Nylon

This fabric merges recycled plastic bottles with high-grade lamination.

It’s popular among sustainable outdoor brands for combining strength, water resistance, and environmental responsibility.

Its smooth surface allows for precision welding and logo heat transfers—ideal for customization.

3. PU-Coated Polyester

Lightweight and cost-efficient, PU-coated polyester suits entry-level waterproof disc golf bags or product lines where affordability matters.

Although not fully waterproof under prolonged exposure, it provides reliable water repellence for light to moderate rain.

4. PVC Tarpaulin (Traditional)

The industry workhorse for decades, PVC tarpaulin remains strong and rigid but carries environmental drawbacks.

Brands transitioning to TPU or rPET alternatives often cite sustainability certifications as part of their long-term strategy.

5. EVA Structural Panels

Used for reinforcing sidewalls and bases, EVA foam adds form stability and protects contents from ground moisture or impact—an underrated but essential detail in long-lasting waterproof performance.

TIP: When sourcing fabrics, ask suppliers for hydrostatic pressure data (mmH₂O rating). Anything below 5,000 mm is water-resistant, not waterproof.

Design Features That Keep Gear Dry

Material choice sets the foundation—but engineering completes the protection.

A waterproof disc golf bag must combine seamless construction, ergonomic comfort, and field-tested practicality.

Here are six must-have design features that every professional bag should include:

- Sealed Zippers – Use YKK AquaGuard or similar models to block water penetration along closures.

- Welded or Taped Seams – Prevent leaks through needle holes.

- Rainfly or Hood Cover – Removable protection for extreme downpours.

- Raised Rubber Base – Keeps the bag off wet surfaces, reducing contact absorption.

- Drain Holes or Mesh Panels – Manage internal condensation and post-rain airflow.

- Ergonomic Shoulder System – Comfort reduces fatigue in humid or cold conditions.

TIP: A bag’s durability often depends more on seam design than on fabric weight.

Real-World Performance: Field Testing Matters

Even the best designs require validation.

Brands that work with experienced manufacturers like Vancharli can benefit from structured field testing across multiple climates.

Whether you’re targeting wet coastal regions, tropical humidity, or northern winter tournaments, testing protocols should evaluate:

- Rain Exposure Simulation: Continuous water spray for 1–2 hours

- Drop Test After Soak: Ensures welded seams don’t separate

- Weight Gain Analysis: Measures fabric absorption after exposure

- Abrasion and Tear Resistance: Verifies coating stability after use

- Dry Time Recovery: Confirms moisture evaporates quickly post-rain

Testing conditions aligned with standards like AATCC 127 or ISO 811 add credibility to product claims.

Professional field testers—especially those accredited by the official guide—can also provide feedback on usability: pocket access with gloves, strap comfort, and disc retrieval speed in the rain.

TIP: Always include user-based field reports in your marketing collateral; it builds authenticity and reinforces trust with retail buyers.

Best Waterproof Disc Golf Bags for Different Conditions

For brands building a full product range, regional weather variation is key.

Here’s how top-performing waterproof disc golf bags align with environmental demands:

| Environment | Challenge | Recommended Protection |

| Rainforest / Wet Woodland Courses | High humidity, persistent rain | TPU tarpaulin with welded seams + full rainfly |

| Coastal or Humid Climates | Salt corrosion, air moisture | rPET-laminated nylon + anti-rust hardware |

| Tournament Environments | Long outdoor exposure, unpredictable rain | Dual-layer waterproof shell + ergonomic frame |

| Winter / Snow Terrain | Freezing conditions, condensation | Elevated rubber base + sealed zippers |

TIP: Match regional weather data with product SKUs—retailers prefer tailored assortments.

Related Gear That Complements Waterproof Bags

For disc golf enthusiasts, a waterproof bag is the centerpiece of an all-weather setup.

Smart brands go further by designing complementary accessories that extend value and margin:

- Rain Gloves and Towels – Maintain grip when discs are wet.

- Umbrella Attachments – Hands-free protection between throws.

- Waterproof Pouches – Keep phones and scorecards safe.

- Quick-Dry Inserts – Add-on accessories that reduce moisture buildup.

- Custom Bag Tags or Branding Panels – Enhance personalization for clubs or teams.

TIP: Bundling accessories increases order value for distributors and simplifies shelf placement for retailers.

Sustainability and Eco-Friendly Waterproofing

Performance and sustainability are no longer separate goals.

Today’s leading brands are demanding materials that are waterproof, durable, and planet-conscious.

Traditional PVC coatings, while effective, have environmental limitations—a fact highlighted in this report.

Vancharli’s approach prioritizes responsible innovation:

- rPET Fabrics – Derived from post-consumer bottles to reduce landfill waste.

- PFAS-Free Coatings – Eliminate “forever chemicals” found in older water repellents.

- TPU Lamination – Combines longevity with recyclability, without toxic plasticizers.

- Energy-Efficient Welding Processes – Lower emissions during assembly.

Brands increasingly seek certifications like GRS (Global Recycled Standard) and Oeko-Tex Standard 100, both achievable through Vancharli’s verified supply network.

TIP: Sustainability adds measurable business value. Retailers report that eco-labeled bags enjoy up to 30% higher consumer preference in Europe and North America.

Manufacturing Waterproof Disc Golf Bags with Vancharli

Producing a waterproof bag isn’t just about fabric choice—it’s about factory capability.

Vancharli is among China’s Top 10 bag manufacturers, with owned production facilities strategically located across China, Vietnam, Myanmar, and Indonesia.

This multi-country structure ensures both cost stability and geopolitical resilience, giving brand partners flexible sourcing options amid shifting tariff landscapes.

Our Technical Capabilities

- High-Frequency Welding & Seam Sealing for complete waterproof integrity

- Advanced Fabric Testing Labs for hydrostatic and abrasion validation

- Custom Mold and Trim Development to match brand identity

- Global Quality Management meeting US, EU, and Japanese standards

- Flexible OEM/ODM Programs starting from 300 pcs per style

- Integrated Sustainability Systems using recycled and PFAS-free materials

With synchronized production planning and material control, Vancharli guarantees consistency whether production happens in China or Southeast Asia.

Each factory operates under unified standards, meaning a brand can launch identical product lines from different countries without compromising performance or compliance.

TIP: A globally distributed manufacturing model ensures faster lead times and smoother logistics—crucial for brands expanding across continents.

Conclusion: Ready for Every Round, Rain or Shine

A waterproof disc golf bag isn’t just about staying dry—it’s about reliability, confidence, and brand trust.

From welded seams to eco-conscious coatings, every design choice signals quality to both players and partners.

Vancharli bridges design vision and scalable production.

Whether your next collection targets premium outdoor athletes or large-volume retail chains, our team ensures every detail—material selection, performance testing, and compliance—aligns with your market goals.

With operations across China, Vietnam, Myanmar, and Indonesia, we provide multi-origin flexibility, stable pricing, and streamlined global logistics—helping your brand weather any market or climate.

Discuss your next waterproof disc golf collection with our global OEM team — one design, multiple manufacturing options.

Visit Vancharli Outdoor to start your project today.

TIP: Weather changes. Professional quality shouldn’t.

FAQ Section

- Are all disc golf bags waterproof?

No. Most are only water-resistant. True waterproof bags use laminated fabrics and welded seams that block water completely. - What materials work best for waterproof disc golf bags?

TPU-laminated tarpaulin and rPET composites provide full waterproofing while staying flexible and durable. - How can I maintain a waterproof bag?

Rinse with clean water after muddy rounds, air-dry fully, and avoid prolonged sunlight exposure to protect coatings. - Can I customize my brand’s waterproof bag?

Absolutely. Vancharli offers OEM and ODM services with complete fabric, logo, and packaging customization. - Do eco-friendly waterproof bags last as long as PVC ones?

Yes. Advanced TPU and rPET fabrics now match or exceed the durability of traditional PVC materials. - Where does Vancharli manufacture?

Across our owned facilities in China, Vietnam, Myanmar, and Indonesia—ensuring flexibility and trade advantage. - What is a rainfly on a disc golf bag?

It’s a detachable waterproof cover that shields the top opening from rain and debris during storms. - Are waterproof disc golf bags heavier?

Slightly—about 5–10% more. But advanced TPU and rPET materials minimize the difference while improving lifespan.

Comments are closed