How Manufacturers Test Waterproof Bags: IPX Standards Explained

Introduction: Why Testing Matters for B2B Buyers

In the world of B2B sourcing, the word ‘waterproof’ is often a marketing buzzword. Many suppliers claim their bags are waterproof, but without verified testing, this statement is meaningless. For brand owners, importers, and wholesalers, waterproof is not just a feature—it is a promise of reliability, durability, and performance.

This is why standardized testing methods like IPX ratings and durability validation have become the benchmark in evaluating waterproof bag suppliers. Understanding how a waterproof bag manufacturer tests its products enables you to reduce supply chain risks, ensure compliance with international standards, deliver consistent quality to your end customers, and protect your brand’s reputation.

Tip: Always ask suppliers for third-party test reports. If a supplier cannot provide them, they may not be capable of meeting true waterproofing requirements.

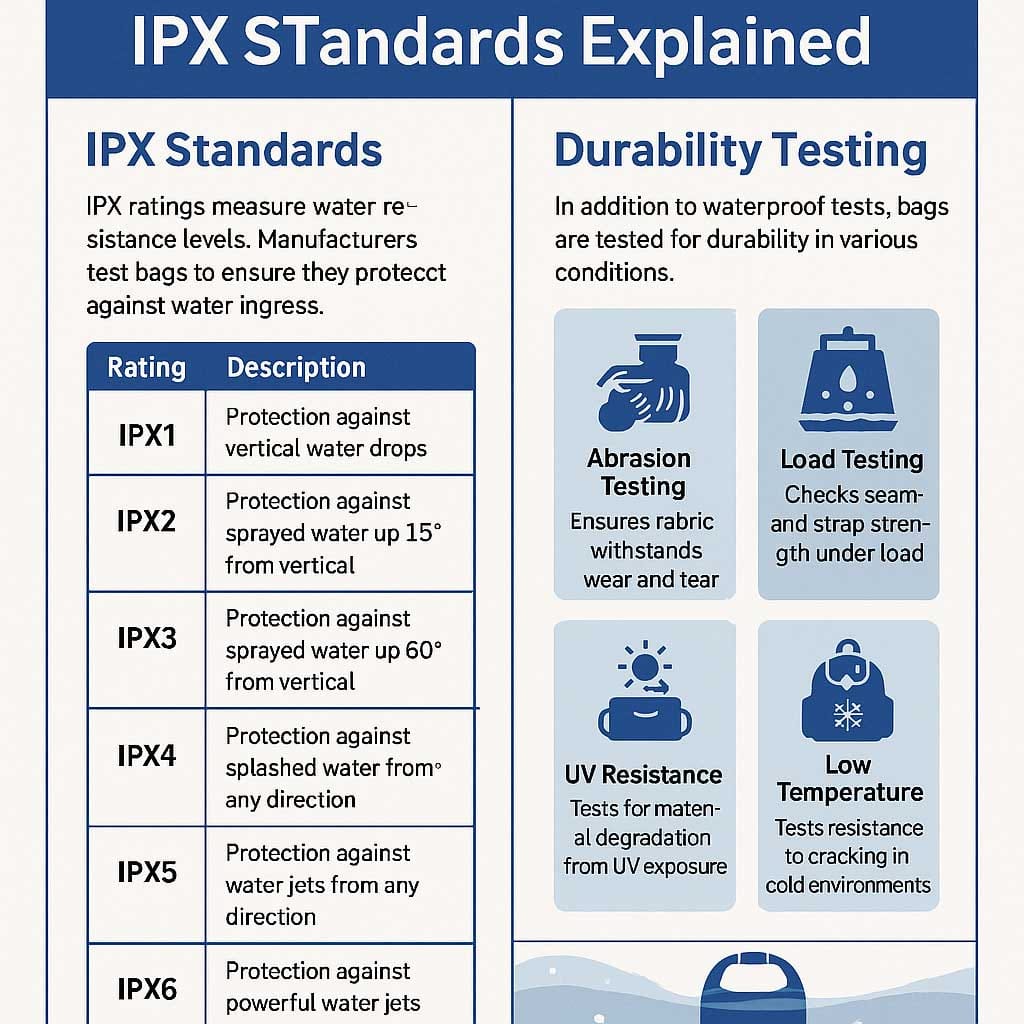

1. What Are IPX Standards?

The term IPX comes from the Ingress Protection (IP) rating system, defined by the international standard IEC 60529. This system is used worldwide to classify the degree of protection an enclosure provides against both dust and water.

When talking about waterproof testing, we usually ignore the dust part (the first digit) and focus on the water-resistance digit. That’s why you see IPX3, IPX5, IPX7, IPX8, etc. The “X” means that the dust protection was either not tested or is not relevant to the product.

For example:

- IP65 would mean dust-tight and resistant to low-pressure water jets.

- IPX5 means dust was not tested, but the product can withstand low-pressure water jets.

For bags, the water part is most critical, so the industry uses IPX-only ratings.

Why It Matters for B2B Buyers

- Consistency: IPX is a globally recognized benchmark, ensuring your products can be compared fairly across suppliers.

- Trust: Many end consumers, especially in Europe and North America, are familiar with IPX. If you can provide IPX7/IPX8 test results, your products gain instant credibility.

- Compliance: Some markets and retailers require IPX certification as part of their quality checklist.

IPX Ratings Table

| IPX Rating | Protection Level | Common Application |

| IPX0 | No protection | Not waterproof |

| IPX3 | Resistant to water spray at up to 60° | Light rain, commuting |

| IPX4 | Splash resistant from any direction | Outdoor, cycling |

| IPX5 | Low-pressure jets (6.3 mm nozzle, 12.5 L/min) | Hiking, heavy rain |

| IPX6 | Strong water jets (12.5 mm nozzle, 100 L/min) | Adventure travel |

| IPX7 | Immersion up to 1 m for 30 minutes | Kayaking, rafting |

| IPX8 | Submersion beyond 1 m (manufacturer defines depth/time) | Diving, underwater photography |

| IPX9K | High-pressure, high-temperature jets | Military, industrial use |

Tip: IPX is not a “marketing invention”—it is an international standard (IEC 60529). Always confirm that the supplier is testing according to this standard, not just doing in-house water splashing.

2. How Manufacturers Test Waterproof Bags

Reliable waterproof bag manufacturers do not rely on claims—they rely on systematic testing.

Amade-Tech, a leading testing equipment supplier, provides IPX1–IPX8 testing chambers, with pressurized immersion tanks that simulate depths up to 50 m. These allow manufacturers to replicate real-life conditions during product validation.

Tip: Always ask which equipment your supplier uses. Testing with professional systems like those from Amade-Tech shows commitment to precision.

| Test Method | Description | Purpose for Buyers |

| Spray Test (IPX3/4) | Exposed to angled spray or oscillating tubes | Simulates light rain or splashes |

| Jet Test (IPX5/6) | High-pressure water jets from 2.5–3 m | Ensures protection during heavy rain or outdoor use |

| Immersion Test (IPX7/8) | Bags submerged at specific depths and durations | Guarantees water-tightness for kayaking/diving |

| Hydrostatic Pressure Test | Measures fabric resistance in mmH₂O | Validates long-term waterproof performance |

| Seam & Zipper Leak Test | Targeted water exposure on weak points | Identifies construction flaws |

3. Immersion Testing: IPX7 and IPX8

IPX7 Testing: Bag submerged at 1 m depth for 30 minutes. Pass criteria: no harmful water ingress.

IPX8 Testing: Depth and duration defined by the manufacturer. Often tested beyond 3–5 m depths, with added parameters (load, temperature, salinity). Pass criteria: bag maintains full function with zero leakage.

Keystone Compliance, an ISO/IEC 17025 accredited lab, offers customized IPX7/IPX8 immersion tests.

Tip: If your market involves diving or marine use, insist on IPX8 results with detailed depth/time data.

4. Materials and Construction That Impact Waterproofing

Waterproof performance is not only about testing—it begins with choosing the right materials and construction methods. Even the strictest IPX testing cannot compensate for poor fabric or weak seams. For B2B buyers, this is a key area to evaluate when selecting a waterproof bag manufacturer.

4.1 Common Waterproof Fabrics

| Material | Waterproof Performance | Advantages | Limitations | Best Use Cases |

| PVC (Polyvinyl Chloride) | Excellent water resistance, high durability | Cost-effective, easy to weld, strong | Heavier, less eco-friendly | Extreme outdoor & industrial bags |

| TPU (Thermoplastic Polyurethane) | Strong waterproofing, flexible | Lightweight, eco-friendly, can be recycled | More expensive than PVC | Premium outdoor, sports, and eco-focused brands |

| Coated Nylon (e.g., 210D, 420D, 600D) | Moderate to high waterproofing (with PU or TPU coating) | Lightweight, cost-efficient | Coating may wear off over time | Backpacks, commuter bags |

| Polyester with PU/TPU coating | Similar to nylon | UV resistant, lower cost | Slightly less durable than nylon | Budget waterproof bags |

| RPET (Recycled PET) | Varies by coating | Sustainable, GRS certified | Higher cost, needs coatings for waterproofing | Brands focusing on eco-friendly collections |

| Canvas with Wax/TPU coating | Splash-proof to waterproof | Natural look, durable feel | Heavy, requires re-coating | Fashion outdoor bags |

Tip: For B2B sourcing, always check the denier rating (D) of nylon/polyester. Higher D (e.g., 600D) means stronger durability, but heavier. Balance weight vs. durability depending on customer needs.

4.2 Construction Techniques

| Technique | How It Works | Waterproof Performance | Cost Level | Best Use Cases |

| RF/High-Frequency Welding | Uses radio frequency + heat to melt fabric edges into seamless joints | ★★★ (Excellent, fully waterproof) | ★★ (Medium–High) | Dry bags, diving bags, premium outdoor gear |

| Hot Air/Heat Sealing | Uses hot air + pressure to bond fabric seams | ★★☆ (Strong, durable waterproofing) | ★★ (Medium) | Outdoor backpacks, mid-to-high end waterproof bags |

| Taped Seams | Stitching covered with waterproof tape | ★★ (Moderate, depends on tape quality) | ★ (Low) | Commuter bags, budget waterproof bags |

| Double-Sided Coating | Both sides of the fabric coated (e.g., TPU on both sides) | ★★☆ (Stable waterproofing, long-lasting) | ★★ (Medium) | Professional outdoor, sustainable collections |

4.3 The Weakest Link: Zippers and Seams

Even with strong fabrics, zippers and seams are the most common failure points in waterproof bags. Understanding their differences is crucial for choosing the right manufacturer and product type.

Zipper Types

| Zipper Type | Waterproof Performance | Cost Level | Durability | Best Use Cases |

| Coated Water-Resistant Zipper | Splash-proof only (IPX3–4) | ★ (Low) | Moderate (coating wears off) | Daily backpacks, commuter bags |

| TPU Airtight Zipper | Sealed against heavy rain & jets (IPX5–6) | ★★ (Medium) | Strong, flexible | Outdoor hiking, sports bags |

| Resin Airtight Zipper | Fully sealed, supports immersion (IPX7–8) | ★★★ (High) | Excellent, long-lasting | Diving bags, professional dry bags |

Seam Construction

| Seam Method | Waterproof Performance | Cost Level | Durability | Weakness |

| Stitched Seams (No Tape) | Poor, water seeps through | ★ (Low) | Low | Not suitable for waterproof products |

| Stitched + Taped Seams | Moderate, resists splashes/rain | ★★ (Medium) | Good, but tape may peel | Long-term use can reduce sealing |

| Hot Air/Heat Sealed Seams | Strong waterproofing, resists pressure | ★★☆ (Medium–High) | Strong | Requires skilled manufacturing |

| RF/High-Frequency Welded Seams | Seamless, fully waterproof | ★★★ (High) | Excellent, no stitch holes | Higher cost, requires equipment |

Tip:

1.For commuter and fashion waterproof bags, taped seams + coated zippers are usually enough.

2.For outdoor and marine applications, insist on RF welded seams + resin airtight zippers to achieve IPX7–IPX8.

3.Always ask manufacturers to provide seam stress test data and zipper open/close cycle results (e.g., 200+ cycles).

5. Waterproof Zippers: The Critical Factor

When it comes to waterproof bags, zippers are often the weakest point—even if the fabric and seams are perfectly sealed. Choosing the right zipper type determines whether a bag can handle just rain or survive full submersion.

5.1 Why Zippers Matter

- High-risk area: Zippers are constantly opened and closed, creating potential leak points.

- Material & design impact: Waterproofing depends on coating, sealing structure, and durability of the teeth.

- Market expectation: Premium outdoor and diving gear buyers expect airtight zippers, while commuters may accept splash-proof types.

5.2 Zipper Types Comparison

| Zipper Type | Waterproof Level | Cost Impact | Durability | Best Applications |

| Coated Water-Resistant Zipper | Splash-proof (IPX3–4) | ★ (Low) | Moderate | Commuter backpacks, fashion bags |

| TPU Airtight Zipper | Rain & jet resistant (IPX5–6) | ★★ (Medium) | Strong, flexible | Outdoor backpacks, cycling, hiking |

| Resin Airtight Zipper | Fully sealed, immersion safe (IPX7–8) | ★★★ (High) | Excellent, long-lasting | Diving bags, professional dry bags |

5.3 Common Testing for Zippers

Waterproof bag manufacturers often conduct specialized zipper tests beyond fabric and seam checks:

1.Zipper Submersion Test – Zipper area submerged in water for 30 min.

2.Cycle Test – 200+ open/close cycles under load, then re-test waterproofing.

3.Pressure Test – Simulated underwater pressure applied directly to zipper.

Tip: For diving and marine applications, resin airtight zippers are mandatory, even though they increase cost. For mass-market bags, TPU airtight zippers balance performance and affordability.

6. Durability Testing: Beyond Waterproofing

Passing an IPX test does not guarantee long-term performance. Durability testing ensures that waterproof bags can withstand real-world conditions over years of use. For B2B buyers, this matters because a bag that fails after a few months leads to warranty claims, damaged reputation, and higher costs.

Typical durability tests

| Durability Test | Why It Matters |

| UV Aging (ISO 4892-2) | Prevents cracking/fading in sun exposure. |

| Salt Spray Test | Ensures resistance in marine conditions. |

| Flex & Abrasion | Tests seams/zippers under repeated folding. |

| Thermal Cycling | Simulates transport/storage in global logistics. |

Tip: Always ask your waterproof bag manufacturer to provide both IPX test results AND durability test data. Together, they prove not only “waterproof” but also long-term reliability.

7. Case Study: Vancharli’s 8-Step Testing Process

With 30 years of experience in waterproof bag manufacturing, Vancharli has developed a rigorous 8-step testing process that ensures every shipment meets international waterproofing and durability standards. Unlike suppliers who rely only on fabric specs, Vancharli tests finished products under real-world conditions.

The 8-Step Testing Workflow

| Step | Test | Description | Why It Matters for Buyers |

| 1 | Rain Simulation Test | Expose bag to 10 L/min water spray for 10 minutes | Ensures bags can handle daily rain exposure |

| 2 | Immersion Test | Submerge bag at 1 m depth for 30 minutes with 5 kg load | Confirms IPX7 compliance for water sports |

| 3 | Hydrostatic Pressure Test | Apply ≥10,000 mmH₂O pressure on fabric | Validates long-term fabric waterproof strength |

| 4 | Seam Sealing Inspection | Visual and water-penetration check on seams | Detects weak spots in stitching or welding |

| 5 | Zipper Submersion Test | Test zippers under water for leakage | Ensures critical weak point is secure |

| 6 | Open/Close Cycle Test | 200+ zipper cycles under load | Proves long-term usability of closure systems |

| 7 | Weight Difference Test | Weigh bag before and after immersion | Measures exact water ingress in grams |

| 8 | Paper Towel Witness Test | Place paper inside bag, re-test with water | Provides visual proof of waterproof integrity |

Why Buyers Trust This Process

Quantifiable Results: Every batch produces measurable data (water ingress in grams, pressure resistance in mmH₂O).

Replicates Real-World Use: From commuting in rain to kayaking, tests simulate actual customer scenarios.

Minimizes Risk: Ensures fewer product failures, lower return rates, and stronger brand trust.

Third-Party Verification: Vancharli partners with accredited labs for random audits, reinforcing transparency.

Tip: When comparing waterproof bag suppliers, ask:

Do they have a standardized testing workflow like Vancharli?

Can they provide sample test reports for recent orders?

Do they allow third-party lab verification before shipment?

Only manufacturers with a consistent, documented process can guarantee performance at scale.

8. Buyer’s Checklist: Questions to Ask

| Requirement | Why It Matters |

| IPX7/8 test report | Validates submersion resistance |

| Hydrostatic data (ISO 811) | Confirms fabric waterproof strength |

| Third-party lab certification | Guarantees credibility |

| Seam & zipper leak results | Exposes weak points |

| Durability test results | Proves long-term value |

9. Application Recommendation Table

| Activity | Recommended IPX | Fabric Hydrostatic Pressure |

| Commuting | IPX4–5 | ≥5,000 mmH₂O |

| Hiking | IPX5–6 | ≥8,000 mmH₂O |

| Kayaking/Rafting | IPX7 | ≥10,000 mmH₂O |

| Diving/Photography | IPX8 | ≥15,000 mmH₂O |

| Military/Industrial | IPX9K | Custom standards |

10. Conclusion

“Waterproof” is a marketing buzzword. But only IPX standards + durability testing prove true performance. For B2B buyers, knowing how a waterproof bag manufacturer tests products helps you select reliable partners, reduce risks, and deliver trusted products to your customers.

Tip: Always balance IPX rating + durability + cost. The right supplier provides the best mix of performance and value.

Learn more about our Waterproof Bag Manufacturer Services

FAQ

1. What does “IPX” actually mean for waterproof bags?

Answer:

“IPX” refers to the waterproof rating defined by the IEC 60529 international standard. The “X” means the product was not tested for dust protection, and the number (0–8) indicates the level of water resistance. For example, IPX5 withstands water jets, while IPX7 allows short-term immersion.

2. Is a higher IPX rating always better?

Answer:

Not necessarily. The rating should match the intended use:

- Urban commuting: IPX4–IPX5

- Kayaking or SUP: IPX6–IPX7

- Submersion or diving: IPX8

Higher ratings often bring higher cost and heavier construction, so the “best” rating is the one that fits the user scenario.

3. Can a roll-top dry bag reach IPX7 or IPX8?

Answer:

Most roll-top dry bags can achieve IPX6 or provide “temporary immersion protection.” However, reaching true IPX7 or IPX8 typically requires reinforced welding, highly controlled sealing structures, and certified lab testing.

4. Do waterproof zippers affect the IPX rating?

Answer:

Yes. Zippers are one of the most vulnerable points in waterproof construction. High-performance waterproof zippers like TIZIP or YKK Aquaseal can significantly increase the IPX level, while standard water-repellent zippers cannot pass immersion tests.

5. Is “waterproof” the same as “water-resistant”?

Answer:

No.

- Water-resistant products handle light rain or splashes.

- Waterproof products pass IPX-grade waterproof testing and tolerate higher pressure or full immersion.

Water-resistant bags will leak under heavy exposure or extended contact with water.

6. Should waterproof bags be tested regularly during production?

Answer:

Yes. Consistent quality requires regular testing throughout production, such as:

- Leak tests

- Pressure and immersion tests

- Seam and weld integrity checks

- Zipper sealing evaluations

Ongoing testing ensures every batch meets the intended waterproof performance.

Comments are closed