How to Test Zipper Strength and Smoothness

You can test zipper strength and smoothness by checking each part for signs of durability and easy movement. Look closely at the tape, teeth, and slider to spot weak points before they cause trouble.

- Zipper fatigue testing helps you see how well a zipper holds up after repeated use.

- Good tests make sure your zipper lasts longer, keeping your clothes or gear reliable.

- Careful checks help you find problems early so you can choose better materials or designs.

Key Takeaways

- Check zippers often to find weak spots like frayed tape or bent teeth. Finding problems early helps stop bigger issues later.

- Test zipper strength by pulling it to see if it breaks or separates. A strong zipper should not break when you pull it hard.

- Test how smooth the zipper is by moving the slider up and down. Clean off any dirt so the slider moves easily.

- Pick zippers that are made from strong materials like brass or stainless steel. These zippers last longer and work better.

- Take care of zippers by cleaning them and using lubricant. If you care for zippers, they will work well for a long time.

Zipper Components

A zipper has several important parts. Each part affects how well the zipper works and how long it lasts. You can spot different zipper types by looking at their materials and shapes.

Tip: Use the table below to learn about each zipper part and its job.

| Component | Description | Contribution to Performance |

|---|---|---|

| Zipper Tape | Woven fabric attached to the bag or garment | Holds the zipper securely to the material |

| Zipper Teeth | Interlocking pieces that open and close | Decide how smoothly and tightly the zipper works |

| Slider | Moves up and down the teeth | Controls how easily the zipper opens and closes |

| Puller | Handle attached to the slider | Lets you grip and move the slider without breaking it |

Tape

The tape is the fabric strip on each side of the zipper teeth. You will often see tape made from polyester. Strong tape keeps the zipper attached to your clothes or bag. If the tape feels weak or frays, the zipper may not last long. Look for tape that matches the color and texture of your item.

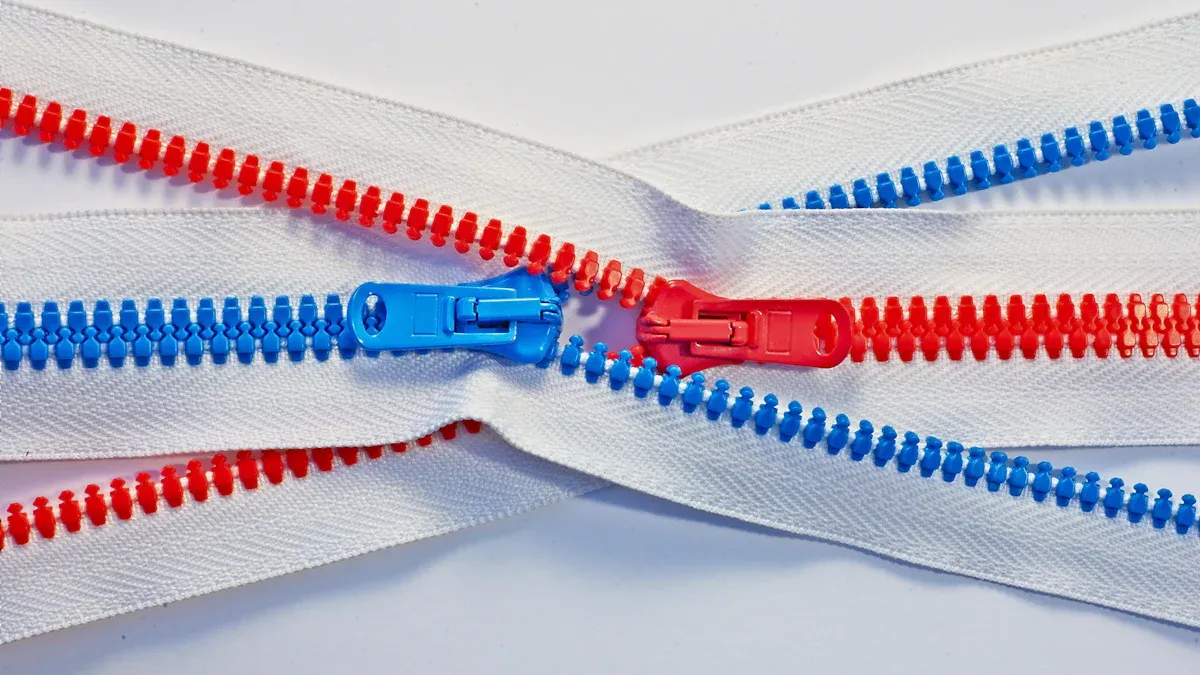

Teeth

Teeth are the small pieces that lock together when you zip up. You can find teeth made from metal, plastic, or nylon coils. Metal teeth look shiny and feel strong. Plastic teeth are bigger and come in many colors. Coil teeth look like a spiral and feel smooth. The shape and material of the teeth affect how easy it is to zip and how much force the zipper can handle.

Slider

The slider is the part you move to open or close the zipper. It connects the teeth and keeps them together. Some sliders feel smooth and glide easily. Others may stick or catch. A good slider should move without much effort. You can spot different sliders by their size and shape.

Box and Pin

The box and pin are at the bottom of some zippers, like those on jackets. The pin slides into the box to start the zipper. If the box or pin bends or breaks, the zipper will not work. Check that both parts fit together tightly and do not wiggle.

Top Stop

The top stop is a small piece at the top of the zipper. It keeps the slider from coming off. You can see the top stop as a tiny metal or plastic piece above the teeth. If the top stop is missing, the slider may fall off when you zip up.

Note:

You can tell zipper types apart by looking at the teeth and tape.

- Coil zippers have thin, flexible teeth.

- Molded plastic zippers have large, stiff teeth.

- Metal zippers have shiny, strong teeth.

Zipper Strength Test

Testing zipper strength helps you find out if your zipper will last through daily use. You can use simple hands-on tests at home or look at how professionals test zippers in labs. These steps help you spot weak points before they become a problem.

Manual Pull

You can start with a manual pull test. This test checks how much force the zipper can handle before it breaks or comes apart. Here is how you can do it:

- Hold the zipper tape firmly at both ends.

- Close the zipper fully.

- Grip the pull tab and gently pull it up and down several times.

- Apply steady pressure by pulling the slider in the direction it would normally move.

- Try pulling the slider at a slight angle to see if it stays attached.

- Watch for any signs of the teeth separating or the slider coming loose.

- If you have a test clamp, you can fix the zipper in place and pull with measured force to see when it fails.

Tip: A strong zipper will not separate, break, or show damage during this test. The slider should stay attached, and the teeth should remain locked together.

Professionals use special machines for this test. They fix the zipper in a clamp, set the tension, and pull until the zipper fails. They check for damage to the tape, teeth, or slider. This method helps measure the exact force needed to break the zipper.

| Test Method | Description |

|---|---|

| Holding Strengths of Separable Units | Tests the strength of the zipper’s separable parts. |

| Holding Strength of Slider Lock | Assesses the locking mechanism of the slider. |

| Holding Strength of Stops | Evaluates the strength of the stops at the ends of the zipper. |

| Resistance to Angular Pull-Off of Slider Pull | Measures the slider’s resistance to being pulled off at an angle. |

| Resistance to Cushioned Compression of Sliders | Tests how sliders withstand compression forces. |

| Resistance to Pull-Off of Slider Pull | Assesses the pull-off strength of the slider. |

| Resistance to Twist of Pull and Slider | Evaluates the twist resistance of the pull and slider. |

| Slider Deflection and Recovery | Measures how the slider deflects and recovers under stress. |

| Strength of Chains and Elements | Tests the strength of the zipper chain and its components. |

| Torsional Resistance of Slider Pull for Removal of Components | Assesses the torsional strength of the slider pull. |

Repeated Use

A good zipper should work after many uses. You can test this by opening and closing the zipper many times in a row. This test checks if the zipper can handle daily wear.

- Zip and unzip the zipper at least 20-30 times.

- Use normal speed and pressure.

- Watch for any sticking, teeth misalignment, or slider problems.

- Check if the slider still moves smoothly and the teeth stay locked.

In labs, experts use machines to zip and unzip thousands of times. They count cycles and look for signs of wear. A high-quality zipper will pass 1,000 or more cycles without failing. This shows the zipper can last a long time.

| Test Name | Purpose | Measurement | Standards |

|---|---|---|---|

| Endurance (Cyclic) Test | Simulates long-term use by repeatedly zipping/unzipping | Cycle counts (e.g., 1,000+ cycles) | ISO 22774 |

| Abrasion Resistance Test | Determines wear resistance from friction | N/A | N/A |

Note: High humidity or extreme temperatures can change how well a zipper works. Heat can make plastic teeth softer and weaker. Cold can make them brittle. Moisture can also make materials softer but less strong. Always test zippers in the conditions where you plan to use them.

Separation Check

You should check if the zipper stays closed under pressure. This test helps you find weak spots that might cause the zipper to split open.

- Close the zipper fully.

- Hold the tape on both sides and pull gently apart, as if you are trying to force the teeth to separate.

- Watch the teeth and slider closely.

- If the teeth pop open or the slider moves without unzipping, the zipper may have a weak bond.

Common failure points include:

| Failure Point | Cause of Failure |

|---|---|

| Zipper Separation | Loose sliders that cannot push the zip coils together |

| Slide won’t close the teeth | Teeth bent out of shape or slider too loose |

| Zipper separates when zipped | Worn-out slider mechanism due to dust |

A strong zipper will keep the teeth locked and the slider in place, even when you pull on the tape. If you see the teeth separate or the slider slip, the zipper may not last.

| Test Name | Purpose | Measurement | Standards |

|---|---|---|---|

| Lateral (Side) Strength Test | Measures resistance to forces pulling the zipper sides apart | Force (N) required to separate teeth or break slider | ASTM D2061, ISO 22774 |

| Vertical (Slider) Strength Test | Assesses slider integrity and tooth retention when pulled vertically | Force causing slider failure or tooth separation | N/A |

| Slider Retention Test | Ensures the slider remains attached under lateral force | Force causing detachment | BS 3084 |

| Tape Strength Test | Evaluates the fabric tape’s resistance to tearing away from teeth | Force required to detach tape from teeth | N/A |

| Top/Bottom Stop Test | Checks stops’ ability to prevent slider detachment | Force causing stop deformation or breakage | N/A |

Alert: If your zipper fails any of these tests, consider replacing it or choosing a higher-quality product. Look for zippers that meet standards like ASTM D2061, ISO 22774, or BS 3084 for best results.

Zipper Smoothness Test

Testing how smoothly a zipper works helps you spot problems before they get worse. You want your zipper to move easily, without catching or sticking. Follow these steps to check for smooth operation and learn how to keep your zipper in top shape.

Sliding

Start by moving the slider up and down the teeth several times. Hold the tape steady and pull the slider in a straight line. The slider should glide with little effort. If you feel any bumps or stops, check for fabric or threads caught in the teeth. Sometimes, dirt or lint can block the path and make the slider stick.

Tip: Clean the zipper with a soft brush or a microfiber cloth. Remove any sand, dirt, or salt deposits. This simple step can restore smooth movement.

You can also test the closing force by pulling the slider at different angles. Use a gentle, steady pull. If you have a force gauge, measure the force needed to zip and unzip. High repeatability in your results means the zipper works well each time you test it.

| Indicator | Description |

|---|---|

| Closing force | Changes with pulling angle; use a force gauge for accurate measurement. |

| High repeatability | Keep the same angle during testing for reliable results. |

Resistance

Check for resistance by locking the zipper and fixing both sides. Try to move the slider while the zipper is under gentle tension. The slider should not catch or stop suddenly. If you feel resistance, look for these common causes:

- Fabric or threads stuck in the teeth.

- Bent or broken teeth.

- Slider getting stuck in the tape.

- Lint or debris blocking the path.

- Zipper design issues, like narrow teeth or weak reinforcement.

Note: Zippers can get dirty quickly. Clean them with water and soap to remove dirt and salt. Use compressed air to blow out dust. Always blow from the inside out to avoid pushing debris deeper.

If the slider moves smoothly and the teeth stay aligned, you have a well-made zipper. If not, clean the teeth and try again. For stubborn resistance, apply a zipper lubricant to help the slider glide.

Teeth and Slider Inspection

Inspect the teeth and slider closely. Look for smooth, even teeth with no sharp edges or gaps. The slider should move without wobbling and stay attached to the tape. Use these tips to spot high-quality parts:

- Check the tape for even color and soft feel. Avoid tape with stains or scars.

- Make sure the teeth have a smooth surface and zip without snagging.

- Test the slider for smooth movement and secure fastening.

- Inspect the hem to see if it fits well with the tape.

- Insert the box and pin to check if they fasten properly.

- Look at the top stop and bottom stop. The top stop should sit close to the first tooth and feel firm. The bottom stop should be flat and secure.

Callout: If you find bent teeth, broken stops, or a loose slider, replace the zipper or repair the damaged part. This will keep your clothes or gear working longer.

To keep your zipper smooth, follow these maintenance steps:

- Clean the teeth with a brush and let them dry before storing.

- Apply a zipper lubricant for easy movement.

- Store items with zippers partially open to reduce tension on the teeth.

- For corroded zippers, scrub with a mix of vinegar and boiling water, then add a protective lubricant.

- If the zipper gets stuck, use a dry lubricant or lip balm to free it.

A smooth zipper makes your clothes and gear easier to use. Regular checks and cleaning help you avoid problems and extend the life of your zipper.

Zipper Quality Signs

Weak Points

You can find weak spots in a zipper by looking and testing. First, look at the zipper closely. See if the slider matches up with the teeth. If the slider looks bent or does not close the teeth, there could be a problem. Move the slider up and down to check if it moves easily. If you feel it stick or see the teeth not match, the zipper might break soon.

Loose threads or fabric can get stuck in the slider and block it. Dirt or small bits inside the teeth can also cause problems. Check if the slider looks worn out. If the slider feels loose or looks damaged, it may not lock the teeth. Look for spaces or uneven spots on the zipper tape. These can make the teeth open by themselves.

Tip: Always test the zipper by opening and closing it a few times. Watch for any catching, sticking, or teeth that do not match up.

Here is a table to help you find common weak points and how to spot them:

| Weak Point | Detection Method |

|---|---|

| Slider Function | Visual inspection, functional testing |

| Teeth Alignment | Visual inspection, functional testing |

| Fabric Obstruction | Visual inspection, functional testing |

High-Quality Indicators

A high-quality zipper uses strong materials and works smoothly. Look for teeth made from brass, stainless steel, or high-grade nylon. These materials last longer and do not wear out fast. The slider should move without sticking or getting stuck. Good zippers are strong and do not break when pulled.

Pick zippers that come in many colors, sizes, and have special coatings. These choices help you find what you need and like. Reliable zippers meet safety and quality rules. Brands like RHF Zipper, CMZ Zipper, Max Zipper, and 3F Zipper are known for being tough and using new technology.

Here is a table of high-quality indicators:

| Indicator | Description |

|---|---|

| Material Selection | Durable materials like brass, stainless steel, or high-grade nylon |

| Smooth Functionality | Operates smoothly without sticking or jamming |

| Strength and Durability | High tensile strength and resistance to wear |

| Customizability | Options for colors, sizes, and coatings |

| Compliance with Standards | Meets industry certifications for safety and quality |

Note: Heavy-duty zippers work well in tough places. Marine-grade and industrial zippers resist sun, water, and scratches. Outdoor gear zippers are extra strong for rough use.

You can test zipper strength and smoothness by following these main steps:

| Step | Description |

|---|---|

| 1 | Visual Inspection: Look for smooth movement and check for defects. |

| 2 | Strength Tests: Test stops, slider lock, and chain strength. |

| 3 | Durability Tests: Zip and unzip many times to check for wear. |

| 4 | Environmental Tests: Try the zipper in different temperatures. |

| 5 | Special Tests: Check for washing and abrasion resistance. |

| 6 | Standards: Make sure the zipper meets quality standards. |

When you buy or repair, always:

- Choose the right material for your needs.

- Test for smooth operation before use.

- Look for strong stitching and secure stops.

Zippers play a key role in product quality and reliability. Always check every part to keep your items working well.

FAQ

How do you fix a zipper that sticks?

You can clean the teeth with a soft brush. Apply a zipper lubricant or a little graphite from a pencil. Move the slider up and down to spread the lubricant. This helps the zipper glide smoothly.

What should you do if zipper teeth do not align?

Check for bent or damaged teeth. Use pliers to gently straighten them. Zip and unzip a few times to see if the teeth catch. If the problem continues, you may need to replace the zipper.

Can you test zipper strength without special tools?

Yes! Hold both sides of the tape and pull gently. Zip and unzip several times. Watch for teeth separation or slider problems. These simple steps help you check strength at home.

How often should you test your zippers?

Test your zippers every few months, especially on outdoor gear or bags. Regular checks help you find problems early. This keeps your items working longer.

What is the best way to clean a zipper?

Use a soft brush or cloth to remove dirt. Wash with mild soap and water if needed. Dry the zipper completely before use. For extra care, apply a zipper lubricant to keep it moving smoothly.

See also

What Can Be Done with Size 2 Fabric

How TPU and PVC Materials Affect Waterproof Performance

Comments are closed