Understanding the Process Flow of Hot Sealed Packaging

Hot sealed packaging uses heat and pressure to make a strong seal. This process helps keep food and other things safe and fresh. This method is very important because the market is growing:

- The hot fill food packaging market could reach USD 86.0 billion by 2035. It is growing at a 4.1% CAGR.

- In 2025, the value might be USD 57.5 billion.

You can make packaging better if you know the right temperatures and pressures. These choices help you get good results and make packaging more eco-friendly.

Key Takeaways

- Hot sealed packaging uses heat and pressure to make strong seals. These seals are airtight. They help keep products safe. They also keep products fresh.

- You must control temperature, pressure, and time very carefully. This helps you get the best seal. It also stops weak seals from happening.

- Pick the right thermoplastic materials for your packaging. This helps make strong seals. It also keeps your product good.

- Check the seals often for gaps or leaks. This keeps things safe and good. You can use pulling tests or thermal cameras to check.

- Always keep your materials and machines clean. This stops contamination. It also helps make strong and safe seals.

Hot Sealed Packaging Basics

What Is Hot Sealed Packaging

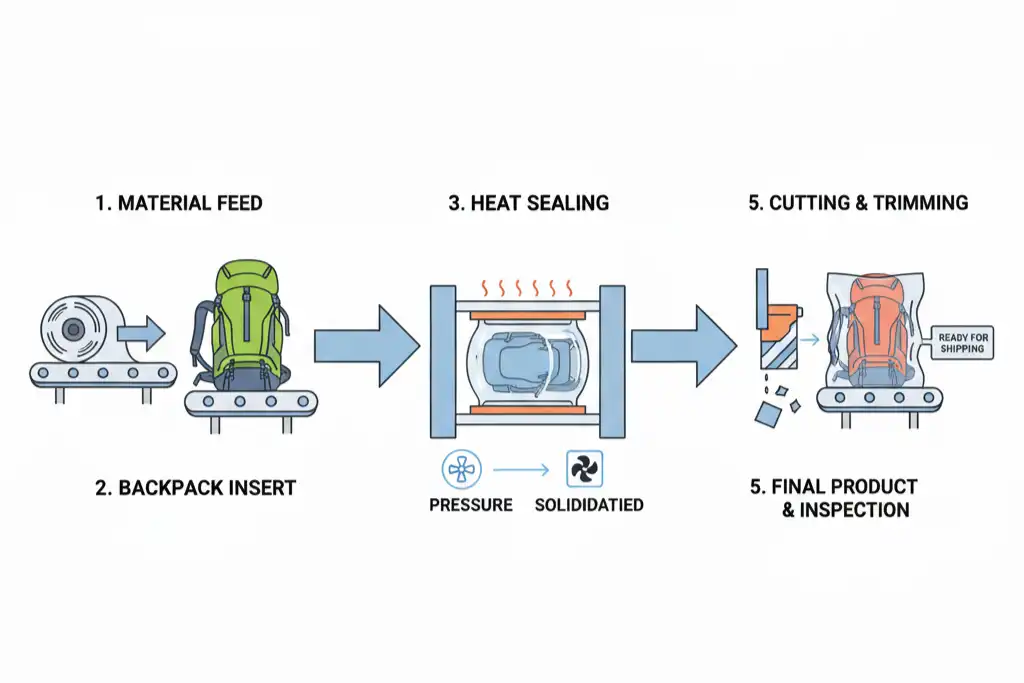

Hot sealed packaging makes a strong, airtight seal on plastic. There are three main steps in this method:

- Melting with heat: Heat is used to melt the plastic where it will be sealed.

- Applying pressure: The melted plastic films are pressed together so they stick.

- Cooling to solidify: The plastic cools down while still pressed, making a tight seal.

You must watch temperature, pressure, and time closely. The right temperature melts the plastic enough to stick. Pressure helps the layers join together well. Time controls how long you heat the plastic, and this depends on the material. If you balance these things, you get a good seal that keeps things safe and fresh.

Tip: Always use clean and matching materials for the best hot sealed packaging.

Common Uses

Hot sealed packaging is used in many industries. It keeps products safe from water, germs, and harm. Here is a table that shows where you might see this method:

| Industry | Common Uses |

|---|---|

| Food and Beverage | – Foods like meats, cheese, and ready meals stay fresh longer. – Snacks like chips and candy do not get wet or spoil. |

| Medical and Pharmaceutical | – Clean items like syringes and gloves stay safe. – Medicines use special seals to show if they have been opened. |

| Industrial and Electronics | – Electronic parts are safe from dust and static. – Hardware and fasteners do not get lost or broken. |

Hot sealed packaging helps keep food fresh, medical tools clean, and electronics safe. This method helps make sure many things you use every day are safe and good quality.

Process Steps

Material Prep

You begin by getting your materials ready. Clean and even materials make strong seals. Most packaging uses thermoplastic materials. These plastics melt with heat and seal tight when cooled. Here is a table that lists common thermoplastics and their uses:

| Material Type | Properties | Applications |

|---|---|---|

| Polyethylene (PE) | Corrosion resistance, great electrical insulation, high melting point, stiff, flexible, strong against impact | Films, corrosion-resistant parts, insulating parts |

| Polypropylene (PP) | Strong, heat resistant, resists corrosion, can break in cold | General mechanical parts, corrosion-resistant parts |

| Polyvinyl Chloride (PVC) | Strong, good electrical performance, resists strong acids and alkalis | Rods, pipes, thin sheets, sealing parts |

| Polycarbonate (PC) | Very strong, high elasticity, resists corrosion well | Small instrument parts, clear insulating parts |

| Polystyrene (PS) | Great electrical insulation, easy to color, can break easily | Clear insulating parts, decorative parts |

Cut your materials to the right size and keep them clean. Dust or oil can make the seal weak. Set the correct temperature, pressure, and sealing time for your material. These steps help you avoid problems later.

Tip: Always make sure your materials fit your product and sealing machine.

Heating and Pressure

Now you use heat and pressure on the packaging. Heat melts the plastic surface. Pressure pushes the layers together so they stick well. You must control both heat and pressure for a good seal.

- The right heat, time, and pressure make strong seals.

- Pressure fills gaps in the film layers and stops leaks.

- Steady pressure gives you good seals every time.

Here is a table that shows how pressure and temperature change the seal:

| Pressure (bars) | Temperature (ºC) | Observations |

|---|---|---|

| 3 | 150 | Sealant polymer starts to squeeze out. |

| 4-5 | >150 | Peel seal changes to lock seal. |

| >4 | 160 | Seal gets damaged and more squeeze-out happens. |

You need to find the right balance. Too much heat or pressure can hurt the packaging. Too little makes weak seals. Automation helps keep heat and pressure steady. This makes your work faster and reduces mistakes.

Cooling

After heat and pressure, you let the seal cool down. Cooling hardens the melted plastic and locks the layers. If you cool too fast, some plastics like polypropylene can break easily. If you cool too slow, your work takes longer.

You can use air or water to cool the seal. Some machines use water with controlled temperature to cool faster. Do not over-cool, or you might get condensation and damage. Cooling the sealing jaws helps you work faster, especially if you have many packages.

Note: Always use the right cooling method for your plastic. This helps you get strong, safe seals.

Inspection

The last step checks if your seals are strong and safe. You can use different ways to inspect:

- Look for gaps, bubbles, or weak spots.

- Test if air or water leaks through the seal.

- Use thermal cameras to check the seal’s temperature.

- Test how much force it takes to pull the seal apart.

- See if the seal can handle pressure without breaking.

- Use dye or gas to find tiny leaks you cannot see.

Test your seals often to catch problems early. This keeps your packaging safe. Automation can help by checking seals quickly and reducing mistakes.

Remember: Careful inspection keeps your products safe and customers happy.

Types of Heat Sealing

Impulse Sealing

You use impulse sealing when you want a quick, safe, and energy-saving way to seal packages. The machine heats up only when you press the sealing jaw closed. This means you do not need to wait for it to warm up, and you save power. Impulse sealers work well for many types of plastic bags and films.

Here is a table that shows why many people choose impulse sealing:

| Advantage/Application | Description |

|---|---|

| Easy to use | You can start sealing right away, which speeds up your work. |

| No warm-up time | You do not waste time waiting, so you finish more packages faster. |

| High safety standards | The machine only gets hot when you use it, so you stay safer. |

| Low energy costs | You use less electricity, which saves money. |

| Clean reliable seal | You get a strong, neat seal every time. |

| Versatile applications | You can use it for food, clothes, medical items, and more. |

Impulse sealing gives you a clean seal and helps you work quickly.

Constant Heat

Constant heat sealing uses jaws that stay hot all the time. You press the jaws onto the plastic, and the heat melts the layers together. You need to watch the temperature closely. If the jaws get too hot, the seal can become weak or even break.

| Method | Efficiency | Seal Quality |

|---|---|---|

| Constant Heat Sealing | Needs careful monitoring; less efficient over time | Seals can be weaker and may leak |

You might use constant heat sealing for thicker materials, but you must check your seals often to make sure they are strong.

Ultrasonic

Ultrasonic sealing uses sound waves to create heat. The machine vibrates very fast, and this friction melts the plastic at the seal point. You do not need to heat the whole machine, so you save energy and work faster.

- You can seal packages in as little as 150 milliseconds.

- The process works well for temperature-sensitive products.

- You use less material, which saves money.

- The machine can handle changes quickly, so you do not wait for it to cool down.

Ultrasonic sealing also pushes dirt out of the way, so you get a cleaner seal. Some materials may not work well with this method, especially if they are very thick or dense.

Hot Bar

Hot bar sealing uses heated bars that keep a steady temperature. You press the bars onto the packaging to melt and seal the layers. This method often needs more energy and takes longer to make each seal. You might use hot bar sealing for large or thick packages.

Here is a table that compares the process flow for each method:

| Sealing Method | Process Flow Description |

|---|---|

| Impulse Sealing | Heats only when the jaw is closed, saving energy and starting quickly. |

| Constant Heat | Uses steady heat, time, and pressure to melt and bond the film layers. |

| Ultrasonic | Uses friction from sound waves to seal, saving energy and improving seal quality. |

| Hot Bar | Uses heated bars at a constant temperature, often needing more time and energy for each seal. |

You can choose the best method for your hot sealed packaging by thinking about your product, speed, and energy needs.

Factors Affecting Quality

Temperature

You need to watch the temperature closely. Heat makes the sealant layer stick to the packaging. If you use too much heat, the seal can get weak or melt the film. Not enough heat means the package will not seal. Each material and machine needs its own temperature setting. Studies show that changing temperatures during fast sealing can make seals stronger or weaker, especially with multilayer films. Always check the temperature where you seal.

Tip: Use a thermometer or thermal camera to check the sealing jaws.

| Key Findings | Description |

|---|---|

| Temperature Dependency | Every package needs a certain temperature to stop problems. |

| Impact of Temperature Gradients | Changing temperature changes seal strength in multilayer films. |

| Defects from Improper Temperature | Wrong temperature causes tiny channels and squeezed-out plastic. |

- Start with the right temperature for good seals.

- Too much heat can bend or change the package.

- Not enough heat makes weak seals.

Pressure

Pressure helps melted layers stick together well. You need to set the right pressure for your material and machine. Too much pressure can break the seal or push out the plastic. Not enough pressure leaves holes and leaks. Change the pressure for different film thicknesses and types. Test your seals to find the best pressure.

Note: Steady pressure gives you the same results every time.

Material Choice

Pick the right material for your product and sealing method. Different plastics need different heat and pressure. Some plastics handle heat better and make stronger seals. Others have special layers to keep food fresh or protect electronics. Using the wrong material can make the seal fail.

| Key Factors | Impact on Sealing Process | Final Seal Quality |

|---|---|---|

| Material Properties | Change heat and pressure settings | Affect seal strength |

| Heat Resistance | Set sealing temperature | Keep seal strong |

| Barrier Characteristics | Stop spoilage and keep taste | Hold product quality |

- The material you choose affects seal strength.

- Barrier layers help keep products safe.

- Good processing helps you get strong seals.

Cleanliness

Keep your materials and machines clean. Dirt, dust, or food bits can make seals weak and cause leaks. Clean surfaces help heat and pressure work better. If you do not clean, products can spoil or become unsafe. Always check and clean sealing jaws and films before you start.

- Clean materials and machines make strong seals.

- Dirt can make products go bad faster.

- Cleaning well keeps your product and customers safe.

Remember: Cleanliness is very important for safe and strong hot sealed packaging.

If you follow each step in hot sealed packaging, you get good results. You need to watch temperature, pressure, and what material you use. This helps you make seals that are strong and airtight. Checking and fixing your machines often stops problems like heat damage or moisture.

- Good sealing keeps products safe and fresh longer.

- Check and clean machines every day to help them work well.

- Change your process for different products and materials.

| Challenge | Solution |

|---|---|

| Overexposure to Heat | Watch and change sealing temperatures |

| Moisture Infiltration | Use coatings that block moisture |

| Environmental Stress | Look at materials for damage |

Try new ways or ask experts for help to make your packaging better for your needs.

FAQ

What materials work best for hot sealed packaging?

You get the best results with thermoplastics like polyethylene (PE) and polypropylene (PP). These plastics melt and seal easily. You should always check if your material matches your sealing machine.

How do you know if your seal is strong enough?

You can test the seal by gently pulling on the package. If it stays closed, the seal is strong. You can also use water or air to check for leaks.

Can you reuse hot sealed packaging?

You should not reuse hot sealed packaging for food or medicine. The seal may not stay strong after opening. For other uses, check if the material is clean and undamaged.

What problems can dirt cause during sealing?

Dirt or dust can make the seal weak. You might see leaks or gaps. Always clean your materials and machine before you start sealing.

How do you choose the right sealing method?

You should think about your product, speed, and material. Impulse sealing works well for most bags. Ultrasonic sealing helps with sensitive items. Hot bar sealing fits thick packages.

Comments are closed